Mystified by all the options in the fastener aisle? I'll show you the different types of wood screws and how to use them for your project!

If you're reading this article, chances are you're staring hopelessly at a huge rack of different screws, trying to decide which one you need for your project. I'm here to help! I'll show you how to choose the perfect wood screw length, width and head type so you can be on your way quickly.

This post contains affiliate links for your convenience. Purchases made through these links may earn me a small commission at no additional cost to you. Please visit my disclosures page for more information.

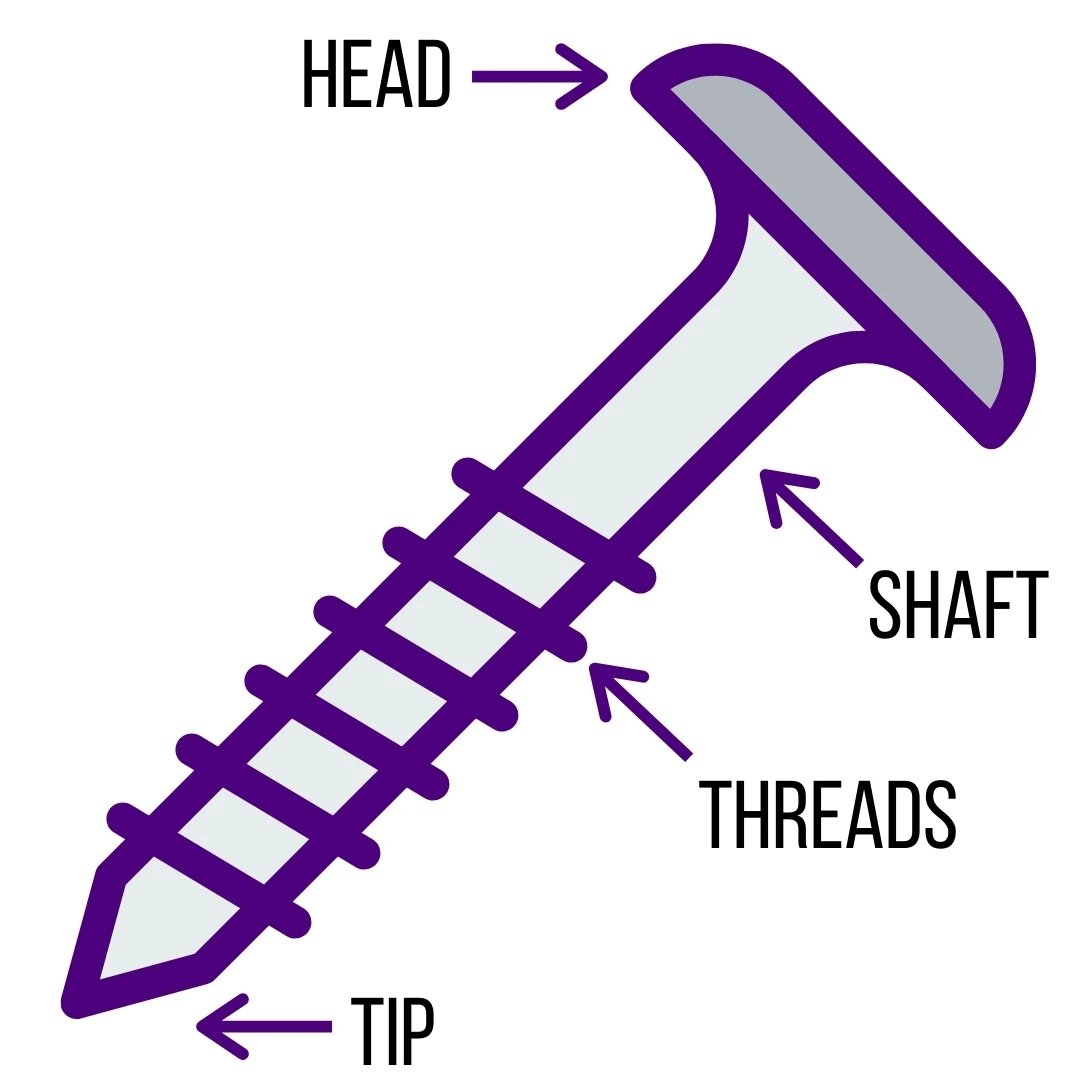

Anatomy of Wood Screws

Before we can go forward, we need to address the different parts of a wood screw. This will take a lot of the mystery out of choosing the right one!

Head of a Wood Screw

The head is where the drill bit twists the screw into the wood. There are three main types, which all serve different purposes.

- Pan head screws. These heads have a rounded top and a flat underside. These screws are best for attaching sheet metal, Plexiglass or other thin materials to a piece of wood. The flat underside sits on top of the surface to hold everything together. You'll need to drill a counterbore hole in order to hide these screws beneath the surface of the wood.

- Flat head screws. These screws have a flat top and a cone-shaped underside, allowing the head to sink into the wood and sit flush to the surface. If your project calls for countersinking screws, these are the ones you want to use. They are used to fasten wood to wood.

- Washer head screws. These screws have a rounded head with a built-in washer. They also have a flat bottom. Washer head screws are commonly used in pocket hole joinery, because the washer part fits into the predrilled hole and holds the two boards together tightly.

Different Drive Types (or Drill Bit Shapes)

The drive type refers to the shape of your drill bit and the corresponding hole in the top of the screw. Here are the most common wood screw drive types:

- Philips head. This head looks like a cross. You're likely familiar with this style. While better than slotted (flathead) drives, Philips head screws tend to bounce out or strip as torque increases.

- Star head or Torx. These are many woodworkers' favorite screws. The star head screw looks like a star with six points. It withstands high torque and seldom bounces loose from your drill. Usually you'll receive a drill bit that matches the size of the star opening in the package of screws!

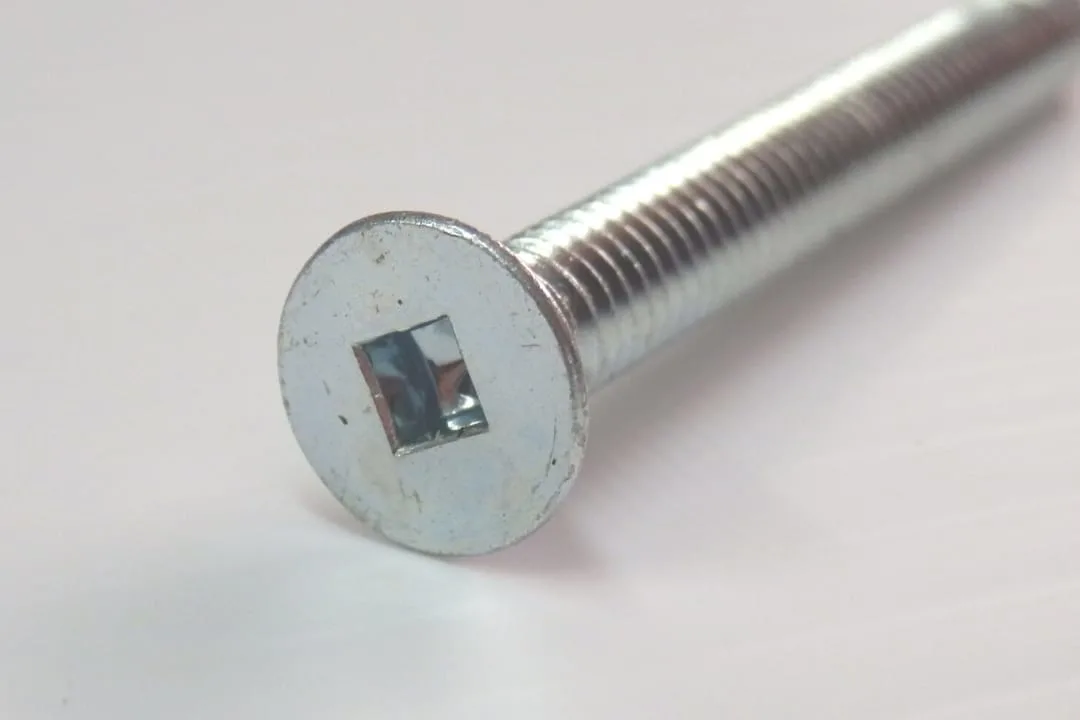

- Square head or Robertson. The square drive is what it sounds like - square. While easier to drive than Philips head screws, these aren't as secure as star-headed screws. This type is commonly found in pocket hole screws.

- Slotted or Flathead. These screws have a single slit across the top to be used with a flathead screwdriver. If you've ever had to replace the plate on a light switch or outlet, you've probably had to use this horrible invention. It's almost impossible to tighten a slotted screw with a power drill, because it will just spin loose.

Shank of a Wood Screw

The shank is the center of the screw. If you imagine a screw without any threads, you've got the shank - kind of like a nail.

The shank is the backbone of the screw and serves several functions.

- Withstands stress. The thicker the shank, the more stress the screw will withstand before it snaps.

- Creates length. Wood screws need to be long enough to hold an even amount between two boards. Too short? Everything falls apart. Too long? It could poke out the other side!

- The non-threaded portion allows for a stronger joint. Ever wondered why the top part of some screws doesn't have threads? Here's why. When you drill one board into another, you want the screw to pull the pieces together. If the whole shank has threads, this doesn't happen easily - the screw will work against itself.

When you predrill a hole, make sure the drill bit matches the diameter of the shank of the screw you'll be using, not the threads! This will leave the surrounding wood intact for the threads to grab onto, giving you the proper hold.

Threads of a Wood Screw

The threads are the spiral part of the screw. Some have different angles or threads per inch, which are used for different types of wood.

- Hardwood screws will have tight threads, meaning many more threads per inch. Hardwoods are less likely to split with these threads.

- Softwood screws have fewer threads per inch to prevent splitting the fibers apart. If you tried to use a screw with tighter threads in softwood, it will have less holding strength. The softer fibers of the wood will tear in the tight threads and will likely just make a screw-sized hole in the wood instead.

Some threads come serrated. These prevent splitting without predrilling and give a stronger hold.

Tip of the Wood Screw

The tip of the screw punctures the surface and drives it into the wood. You might see these terms when shopping for wood screws:

- Self-drilling tip. Wouldn't it be nice to avoid predrilling? Well, that's what the self-drilling tip does. On some wood screws, you'll see a notch cut into the bottom of the threads. This notch eats away the wood as the screw turns and helps prevent splitting.

- Flat tip screws. Some screws have a flat tip. These aren't commonly used for woodworking - they are often called machine screws for metal fastening.

Some tips of wood screws will be very sharp to poke deep into the wood and prevent the screw from wandering away. However, you may find some screws are blunter - these are best suited for predrilled holes, especially in hardwood.

Materials Used to Make Wood Screws

Wood screws are made from several types of metal. Which one you choose depends on where your project will be located (indoors or outdoors) and how much abuse it will take.

- Steel. Many base-level screws are made out of hardened steel. Steel is durable under stress and quite resistant to spin out when driving the screw into place. However, steel can corrode and rust, so it's not recommended for outdoors.

- Stainless Steel. Stainless steel offers most of the benefits of steel without the rust problem. Many exterior screws will come with a special coating to further inhibit corrosion.

- Brass screws. Brass screws are fancier and typically used for more decorative work, like small hinges. Brass screws tend to be softer, so be careful when driving them. You don't want to get stuck trying to remove a stripped screw from your finished project!

Understanding Wood Screw Terminology

When you go to the screw section at a hardware store, it can feel like going to a library without knowing the Dewey Decimal System. Here's how to read those signs and pick the right wood screw for your project.

Here are a few terms you'll need to know:

- Gauge of a screw. The gauge of the screw refers to the thickness of the shank or the minor diameter. The major diameter would be the diameter of the shank, including the thread. Both are important; however, the minor diameter is what affects the screw's toughness. The larger the number, the thicker the screw.

- Length of a wood screw. Typically expressed in inches. Your screw should be long enough to have an equal amount of shaft in the top and bottom board without the tip breaking through the other side.

- Pitch of a wood screw. The pitch refers to the screw's threads per inch. A softwood screw will have fewer threads per inch or less pitch, and a hardwood screw will have more threads per inch or higher pitch. This isn't always expressed as a number printed on the box, but it will typically say whether the screw is made for softwood or hardwood.

Now let's put this all together at the hardware store.

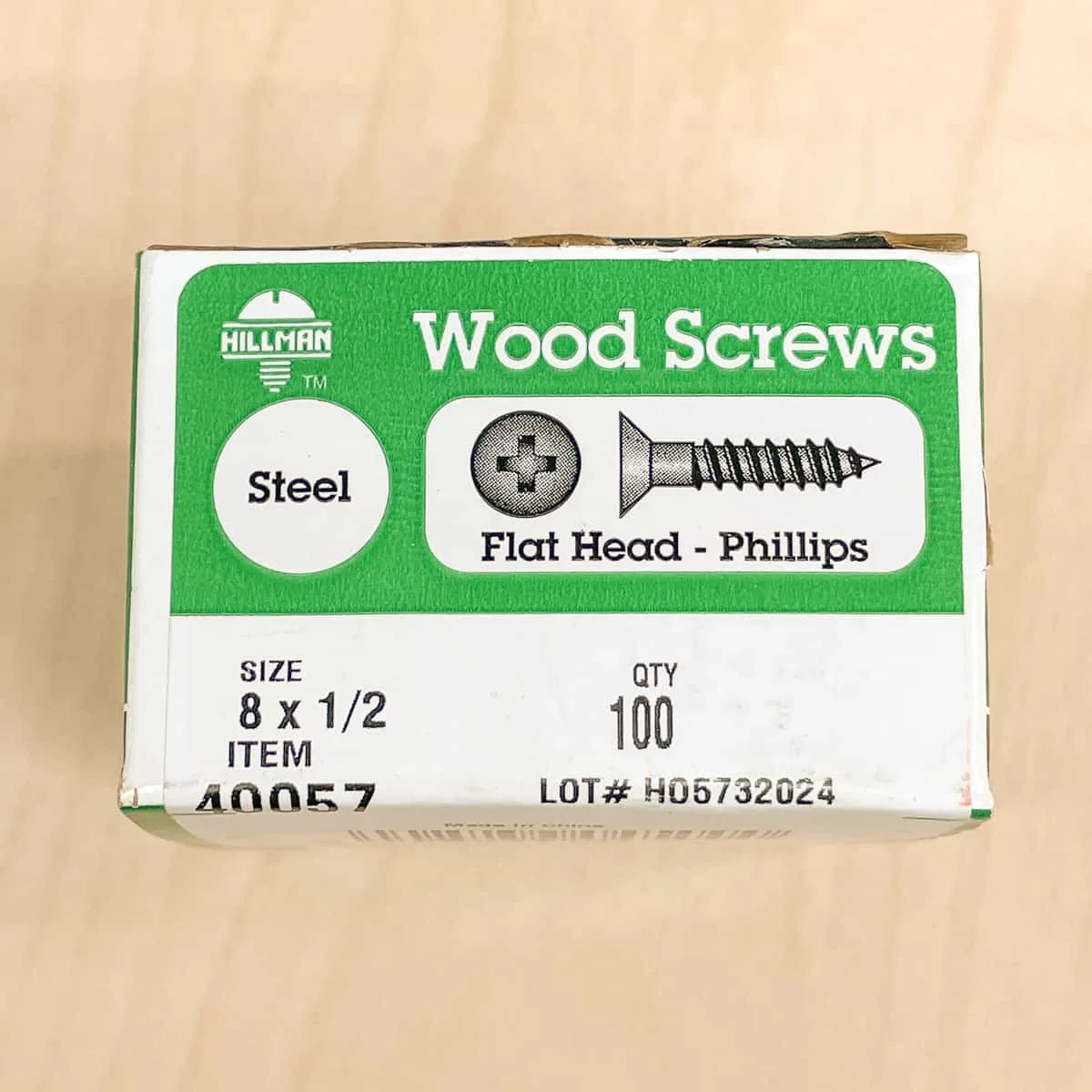

How to Read a Box of Screws

Each brand of screw will have a different type of box, but the information is always the same. Typically, a box will list two main numbers. The gauge of the screw and the length of the screw. Other helpful information such as the material or intended use (indoor/outdoor), type of head and drive should also be listed somewhere on the box.

See those numbers? What do they mean?

The "8" stands for the gauge, and 8 is a pretty standard size that you'll use frequently. The ½ means the screw is half an inch in length. They're made of steel, so we know they're only meant for interior use. It has a flat, Philips head, so you could countersink these screws with a standard X shaped drive bit. I keep these small screws in my workshop for attaching thin ¼" plywood to the back of cabinets.

Let's try a more complicated box!

These are some of my favorite screws! The "10" stands for the gauge, which means that the shaft on these screws is thicker than the previous box. The 2 ½" is the length of the screw. Normally I use this size when working with 2x4 lumber.

It clearly indicates that these are exterior screws with a special coating to prevent rust. It has a star head with a bit that's included in the box (love that!), and a special tip so you don't have to predrill to prevent splitting the wood.

Hopefully this guide to wood screws was helpful! Once you understand the wood screw sizes and types, you can quickly grab the one you need at the store and get building!