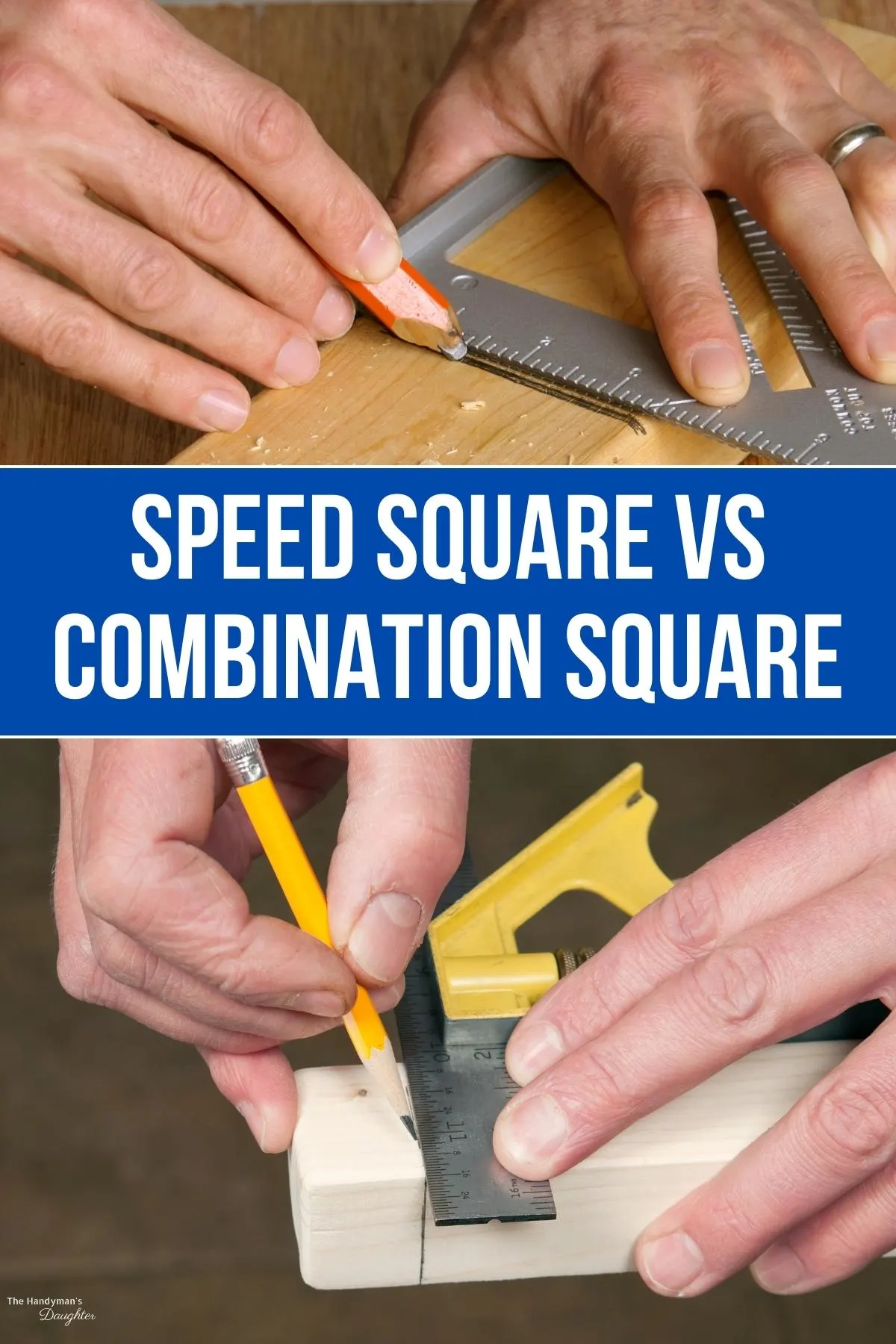

Discover the pros and cons of a combination square vs speed square, comparing features and applications for precise woodworking.

In the world of woodworking and construction, accuracy and precision are paramount for achieving exceptional results. Whether you're a seasoned professional or a total newbie, having the right square at your disposal is a must.

There are so many different types of squares available nowadays, but the most common ones are the speed square and the combination square. Each of these tools has its unique strengths and weaknesses, so it's important to know which one to use when.

In this article, we'll dive into the details of these two indispensable tools, compare their features, and discuss when to use them, helping you make an informed decision on which square best fits your needs.

This post contains affiliate links for your convenience. Purchases made through these links may earn me a small commission at no additional cost to you. Please visit my disclosures page for more information.

Speed Square vs Combination Square Comparison

Let’s start by talking about some of the characteristics of each of these tools. As you’ll see, there's some overlap, but they're not necessarily interchangeable. After this quick list, we’ll go into each type in more depth!

Combination square characteristics

- Versatile design: Consists of a ruler, square head, protractor head, and center finder, offering multiple measuring and marking functions.

- Adjustable heads: The sliding heads can be locked in place at any point along the ruler, allowing for repeatable measurements.

- 90-degree and 45-degree angles: Combination squares can measure both right and mitered angles with ease.

- Scribing tool: Built-in scribing pin or awl for marking lines and reference points on workpieces.

- Depth gauge: Useful for measuring the depth of holes, grooves, or recesses.

- Material options: Available in steel, cast iron, or aluminum, providing durability and rigidity.

- Precision: Combination squares are known for their accuracy, making them a popular choice among professional woodworkers and machinists.

- Graduated ruler: Can feature both imperial and metric scales on the same ruler.

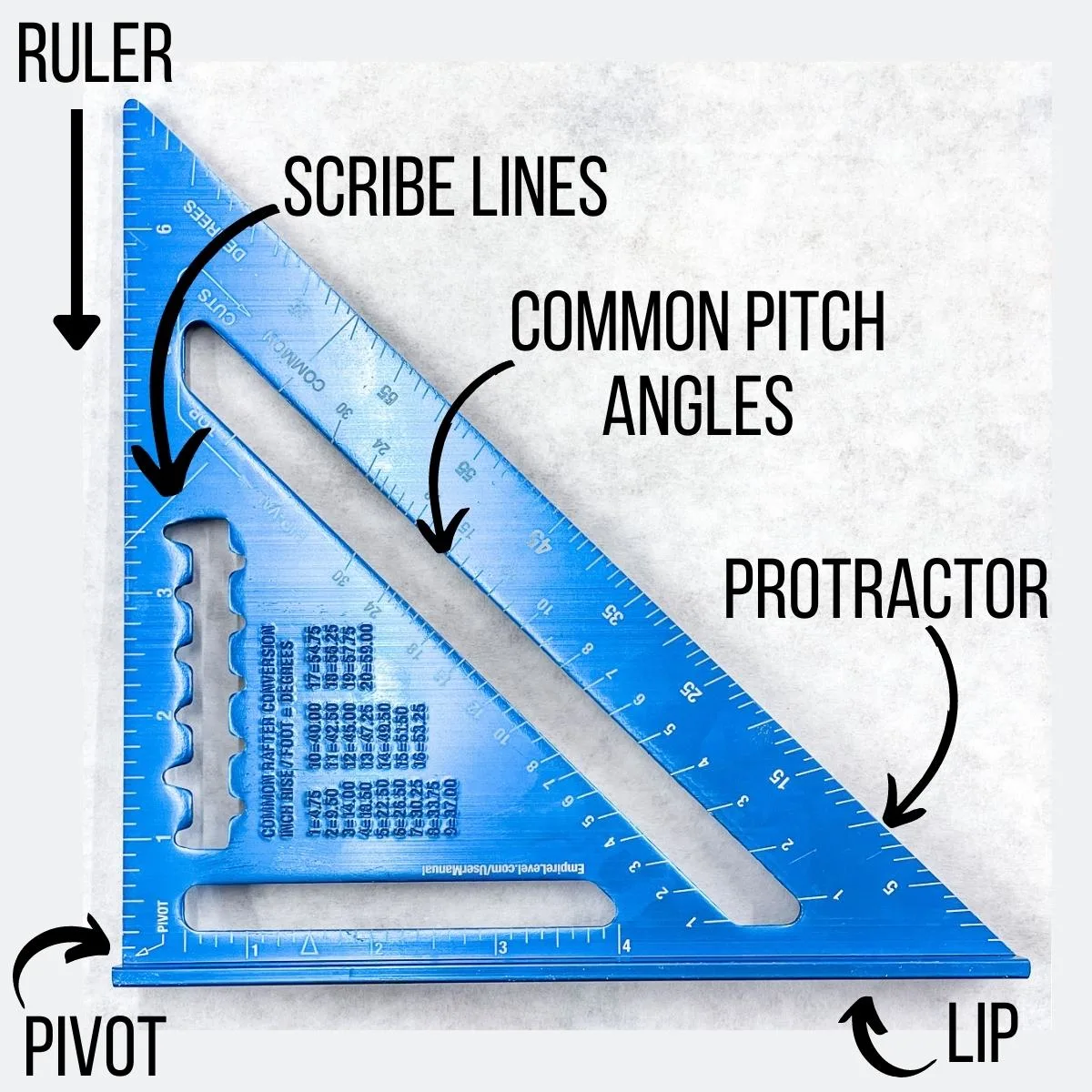

Speed square characteristics

- Triangular shape: The L-shaped design is easy to use.

- Lightweight: Typically made of durable plastic or aluminum.

- 90-degree and 45-degree angles: Speed squares have easy to read markings for quick measurements.

- Saw guide: You can use the edge as a guide for the base plate of a circular saw or jig saw.

- Rafter tables: Essential for roof pitch calculations and determining rafter lengths.

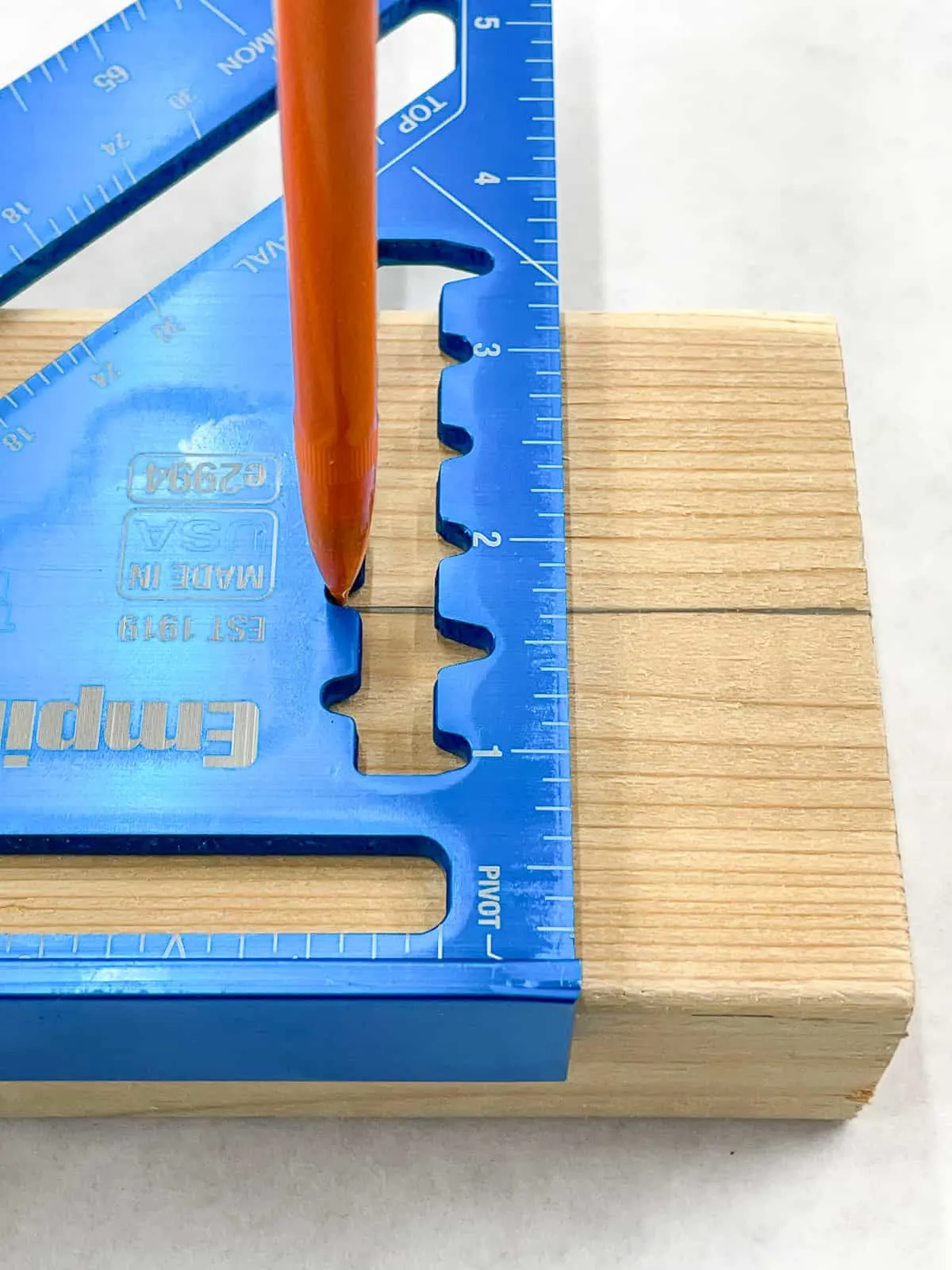

- Scribing notches: Used for marking rip cuts or parallel lines along the edge of a workpiece.

- Pivoting function: Allows for marking angles other than 90 or 45 degrees by aligning the pivot point with the edge of the material.

- Ease of use: The compact size and straightforward design make it an accessible tool for users of all skill levels.

- Cost-effective: Generally more affordable than combination squares.

Okay! Now that we have a rough understanding of how these two measuring devices work, let’s get into some of the details.

What is a Combination Square?

A combination square is a versatile measuring and marking tool widely used by woodworkers, metalworkers, and DIYers for its precision and adaptability. This multi-functional tool is designed to perform a range of tasks, from marking right angles and miter cuts to measuring depths and finding the center of round objects.

It consists of a graduated ruler, typically made of steel, and one or more interchangeable heads. The square head is used for measuring and marking 90-degree and 45-degree angles. The ruler slides through the head and can be locked in place at any point, allowing for repeatable markings.

You can buy the square head and ruler on its own, or get a set with other useful attachments. The protractor head is used for measuring and marking angles other than 90 or 45 degrees. The center finder is for finding the center of round or cylindrical objects.

When Should You Use a Combination Square?

A combination square is generally the better choice for tasks that demand high accuracy, a wider range of angle measurements, and additional functionalities like depth gauging and center finding.

You should consider using a combination square instead of a speed square in the following scenarios:

- Precision measurements: Combination squares are known for their accuracy and can provide precise measurements, making them ideal for detailed woodworking, metalworking, or machining projects.

- Measuring and marking angles other than 90 or 45 degrees: You can use the protractor head to measure and mark a wide range of angles.

- Depth measurements: Combination squares come equipped with a depth gauge, which is useful for measuring the depth of holes, grooves, or recesses. Speed squares do not have this functionality.

- Center finding: If your project requires finding the center of round or cylindrical objects, a combination square with a center finder attachment is the right choice.

- Scribing lines and reference points: The built-in scribing tool on a combination square makes it easy to mark lines and reference points on workpieces, while speed squares only offer scribing notches for rip cuts and parallel lines.

- Measuring smaller workpieces: Combination squares are generally more suited for smaller and more intricate workpieces, thanks to their fine measurement markings.

What is a Speed Square?

A speed square doesn’t get its name from its shape (it looks like a triangle!), but it is quick to use. Unlike the combo square, the speed square has no moving or removable parts. The speed square is a single, solid tool.

Constructed from lightweight materials like aluminum or durable plastic, speed squares are designed for quick and easy measurements, particularly when marking 90-degree and 45-degree angles.

The tool's hypotenuse features built-in angle markings, allowing users to measure and mark various angles for tasks like cutting rafters, trim work, or stair stringers. Additionally, scribing notches can be used for marking rip cuts or parallel lines along the edge of a workpiece.

Check out this article on how to use a speed square for more information on these techniques.

When Should You Use a Speed Square?

A speed square is a better option for tasks that demand quick angle measurements, roofing and framing projects, acting as a saw guide, marking rip cuts, or working with larger materials.

Consider using a speed square instead of a combination square in the following situations:

- Quick angle measurements: Speed squares are specifically designed for making fast and accurate 90-degree and 45-degree angle measurements.

- Roofing and framing tasks: The built-in rafter tables and angle markings on a speed square are helpful for calculating framing-related measurements.

- Saw guide: You can use the speed square's straight edge as a saw guide for making precise crosscuts and angled cuts with circular saws, jig saws, or handsaws.

- Marking rip cuts or parallel lines: The scribing notches on a speed square make it easy to mark rip cuts or parallel lines along the edge of a workpiece.

- Working with larger materials: You can find large speed squares that are great for marking and measuring larger workpieces, such as plywood.

- Budget constraints: Speed squares are generally more affordable than combination squares.

I have multiple speed squares and combination squares scattered across my workshop, so I always have one close at hand. Which one do you reach for first? I'd love to hear about your experiences in the comments below!