Are polycrylic and polyurethane the same thing? When should you use one or the other? In this article, we'll explore each of these finishes.

Polycrylic and polyurethane are both clear top coats that can be applied over stain or raw wood to create a protective finish. Polycrylic is water based, and polyurethane is oil based (though there are some water based polyurethanes).

There are differences between these two finishes that will affect your project. In the sections below, I compare polycrylic vs polyurethane and help you decide when you should use each product.

Let’s jump in!

This post contains affiliate links for your convenience. Purchases made through these links may earn me a small commission at no additional cost to you. Please visit my disclosures page for more information.

What are the major differences between Polycrylic vs Polyurethane?

You'll find both these protective top coat options have distinct characteristics that may make one better suited for your project.

- Polycrylic is water based and doesn't off-gas as many volatile organic compounds as oil based polyurethane.

- Polyurethane is considered more durable than polycrylic.

- Polycrylic dries faster; however, you need more coats to achieve the same effect.

- Polyurethane has greater water resistance than polycrylic.

- Polycrylic is easier to clean due to being water based.

- Polycrylic tends to dry to a clear or slightly milky hue.

- Polyurethane tends to dry with a slight yellowish tint.

Okay, now you've got some idea of the difference between these two products. Let's take a look at each of them in more detail.

What is Polycrylic?

Polycrylic is a water-based sealer used as a protective finish on stained and raw wood. It can also be used over latex paint.

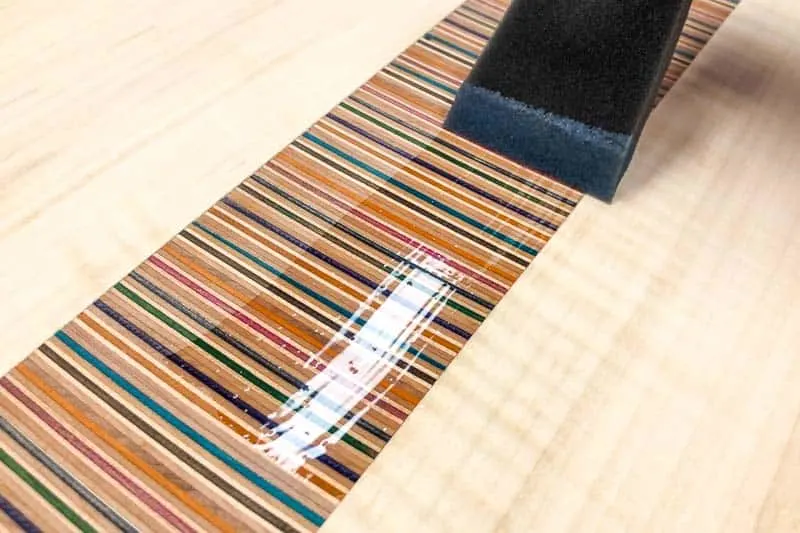

It's my favorite top coat for light woods like maple, because it enhances the natural color instead of turning yellow. You can see how it brightens the colors of the dyed wood veneers of this DIY laptop stand top.

Polycrylic offers several nice features:

- Water based. If you hate cleaning your brushes with paint thinner, you'll enjoy working with polycrylic. It's water based, so a little soap and warm water will remove it easily.

- Fewer fumes. Polycrylic is low odor, although you should always work in a well ventilated area when applying a polycrylic finish.

- Fast dry time. Polycrylic dries within an hour or so, allowing you to apply thin coats faster than you could with polyurethane.

- Dries clear. Oil based finishes tend to leave an amber hue on wood surfaces, which may not be the look you're going for. Polycrylic is a better option for light woods or furniture that is painted white.

When should I use Polycrylic?

Polycrylic is a great finish for wood projects, but it has its drawbacks too.

- Low contact areas. If you're finishing picture frames or something that doesn't get a lot of use, you probably don't need the added durability. But for areas with heavy foot traffic like floors, polyurethane is the better choice.

- Light areas. If you're applying a finish over light paint or wood, you'll be happy to know that polycrylic doesn't usually alter the color. Polyurethane tends to dry with a slightly yellow tint (even when it's advertised as "clear coat" - you learn this one the hard way)

- Not heat resistant. High temperatures can discolor polycrylic and cause it to bubble, so it's not a good choice for finishing kitchen cabinets near the stove.

How to apply Polycrylic

Polycrylic can be brushed, rolled or sprayed on, depending on your project. Here are some tips for getting the best results:

- Safety. Wear a mask and eye protection while sanding. Also, work in a well ventilated area to prevent the build-up of fumes.

- Choose the right sheen. Just like with paint, clear top coats also have different sheens to choose from. These can range from ultra flat to high gloss.

- Sand. The smoother your wood surfaces are, the better your finish will look. Work your way through the sandpaper grits up to 220 for an ultra smooth surface.

- Remove any dust. Dust is the enemy of a good clear finish. Use a vacuum to suck up the majority of the debris, then wipe down the surface with a tack cloth to remove the rest. You can also clean the surface with mineral spirits.

- Apply thin coats. Use a high-quality bristle or foam brush to apply very thin coats. Use long strokes and avoid brushing over wet areas to ensure the finish is even. Make sure to catch any drips on a vertical surface before it dries into a blob!

- Lightly sand between coats. Use high grit sandpaper (200-400 grit) to smooth out any brush strokes after the surface is dry. Avoid using steel wool, which can leave little bits of metal in the finish. Sanding also promotes adhesion for the next layer. Be sure to clean all the wood surfaces again before applying the next coat.

- Repeat. Follow the instructions on the polycrylic container regarding dry time. Usually, it's at least an hour. You may need to apply up to six coats to get the desired level of protection!

Frequently Asked Questions about Polycrylic

Can Polycrylic be used over paint?

Yes, you can use polycrylic over paint. This is an especially good idea if the paint is in a high-wear area, like a door or cabinet. However, it can leave a milky appearance on dark colored paints, so test in an inconspicuous spot on your painted furniture before committing.

Will Polycrylic yellow over white paint?

Unlike polyurethane, polycrylic shouldn't turn yellow over white paint. However, there are many different brands of polycrylic and different conditions, so be sure to test it first!

Is Polycrylic waterproof?

Polycrylic is water resistant, but since the finish is water-based, it won't provide the same level of waterproofing as oil based polyurethane finishes. Check out all the options for waterproofing plywood here!

What is Polyurethane?

Polyurethane is one of the most popular finishes used in woodworking and DIY projects. Oil based polyurethane is the most common, although you can find water based polyurethane as well.

Here are a few things to know about polyurethane:

- Durable. The main claim to fame for polyurethane is its durability. It resists scratches and protects the wood underneath.

- VOCs. Oil based poly has more VOCs and a strong odor. For this reason, some people might choose water based poly, although it still has more volatile organic compounds than polycrylic.

- Dry time. Polyurethane can have much longer dry times than polycrylic - up to 24 hours. So, though you don't need as many coats, it can still take longer to apply.

- Heat resistance. Polyurethane is more heat resistant than polycrylic - something to consider if your project will sit in direct sun or near a heat source.

When should I use Polyurethane?

Here are several good times to reach for the polyurethane:

- Hardwood floors. Wooden floors take a lot of abuse! So, it makes sense to protect it with a durable finish.

- Bare wood. Even if you don't use stain, you can protect the wood with polyurethane. This will help the grain stand out and give your wood a layer of protection.

- Doors. Doors are often kicked and bumped. If you want to prevent damage, polyurethane can help.

Here are several times to avoid oil-based polyurethane:

- Over white paint. Polyurethane, even the stuff that says it is a clear coat, will leave a yellow tinge over white paint. Always always test any finish in an inconspicuous area before applying it to an entire project.

- Low contact areas. If you're applying a finish to something that won't be bumped or scratched, then you may want to stick with polycrylic.

How to apply Polyurethane

Polyurethane, like polycrylic, can be brushed, rolled or sprayed on, depending on your project. Many of the steps are the same as polycrylic, so check out that section above for more details. However, there are some specific guidelines to keep in mind.

- Safety. Polyurethane contains more harmful fumes than polycrylic. For this reason, be sure to work in a well ventilated area and wear a respirator.

- Prepare the surface. All the wooden surfaces up to 220 grit for a smooth finish.

- Clean the surface. Remove all sawdust and debris.

- Apply the first coat. Use a high-quality bristle or foam brush. Apply in long, even strokes.

- Allow it to dry. It may take up to 2 hours for each coat to dry. Check the label on the can for specific times, and don't rush it! Otherwise, your polyurethane could be forever sticky.

- Repeat coats. Repeat the coats until you achieve your desired level of finish and durability.

Frequently Asked Questions about Polyurethane

Is Polyurethane toxic?

Most polyurethane releases VOCs or volatile organic compounds - these can be harmful. However, the danger depends on how concentrated the VOCs are, and how sensitive the person is to the fumes. For this reason, it's best only to use polyurethane with high VOCs when absolutely necessary, wear a respirator that filters out chemicals and ventilate the area.

Is one coat of Polyurethane enough?

Typically, you should apply at least two coats of polyurethane for the best results. For example, a wood floor or a door might need up to three coats (or more), as these are high-traffic areas. However, you don't need as many coats if you're just trying to seal a wood surface.

Is Polyurethane a hard finish?

If you apply it correctly, polyurethane is durable and hard. However, this will depend on how long you allow it to cure and the type of polyurethane you're using.

Now that you know the difference between polycrylic vs polyurethane, you can make an informed decision about the right finish for your project!

Check out these other finishing tutorials!

Jo H.

Saturday 13th of August 2022

Hello! You have a great website, though I'm still hesitant about my project. I'm all done sanding kitchen cabinet doors that had been finished with a clear coating of some kind. I like the bare wood look. I'm now ready to apply the protective finish but discovered that I bought clear satin Minwax Polycrylic, rather than Polyurethane, which I had intended to buy! What do you think? Should I try to exchange the product or would you proceed with the Polycrylic? I have cupboard doors next to a dishwasher and next to a stove.

Vineta Jackson

Thursday 1st of September 2022

Either one should be fine for your cabinet doors. It really depends on the look you're going for. The polycrylic will keep it looking like bare wood, and polyurethane will give it a deeper, amber hue.

Shelley

Saturday 16th of July 2022

If a painted cabinet also coated with polycrylic scratches ,dents, or needs to be repainted can it be painted over , or does one have to sand all the Polycyrylic off first ? Thanks

Vineta Jackson

Monday 25th of July 2022

You might be able to just use liquid deglosser on the scratched or dented areas to remove the polycrylic before repainting. I would test in an inconspicuous spot (like the back or inside) to see if paint will stick to it first.

Mike

Tuesday 29th of March 2022

Thanks for the information. I do have a question though. I have sanded 20 year old rough sawn lumber in a cabin. I like the idea of polycrylic, but if I used polyurethane could I skip the sanding between coats. I standed the entire ceiling which has a peak 20 feet above the floor and I really don't want to have to sand it again. Thanks!

Vineta Jackson

Wednesday 30th of March 2022

I don't blame you, I wouldn't want to sand that again either! I would do a test on a small area to see which product gives you the color and sheen you're looking for before committing to the entire ceiling.

Teresa J Shearer

Wednesday 16th of March 2022

Thank you! This really helped me!

Vineta Jackson

Thursday 17th of March 2022

So glad I could help!