Confused about the difference between a diode and CO2 laser? Here's everything you need to know about the pros and cons of both machines!

Are you debating between getting a diode or a CO2 laser cutter for your hobby or small business? Both types of machines can cut and engrave similar materials, such as wood, colored acrylic, and tumblers. So which one is right for you?

This table shows a quick side-by-side comparison of a diode vs CO2 laser.

| Feature | Diode Laser | CO2 Laser |

|---|---|---|

| Wavelength | Shorter wavelength (blue light) | Longer wavelength (infrared light) |

| Engraving | Can engrave wood, some dark opaque acrylic, MDF, plated or coated metal, dark glass, cement, ceramic, stone, cardboard, fabric, felt and leather. | Can engrave all acrylic colors, wood, MDF, leather, fabric, glass, rubber, cement, ceramic, stone, cardboard, and plated or coated metal. |

| Cutting | Can cut wood, some dark opaque acrylic, MDF, cardboard, fabric, felt and leather. Cannot cut clear, white or blue acrylic. | Can cut all acrylic colors, wood, MDF, leather, fabric, glass, rubber, cardboard, foam. |

| Power | Generally lower power (5W - 40W+) | Higher power options (40W - 300W+) |

| Beam Focus | Tighter, smaller beam spot. Good for fine detail engraving. | Larger beam spot, better for cutting and deep engraving. |

| Cost | Generally more affordable | More expensive |

| Size | Often smaller and more portable | Larger, heavier and bulkier |

| Maintenance | Minimal maintenance required | More complex maintenance (laser tube, mirrors, alignment) |

I own both the xTool M1 diode laser and the xTool P2 CO2 laser. I'll go into more detail about my experience with both types of machines in the article below!

This post contains affiliate links for your convenience. Purchases made through these links may earn me a small commission at no additional cost to you. Please visit my disclosures page for more information.

Don't have a laser, or looking to upgrade? Use the code VINETA100 for $100 off an xTool laser! Click here to check them out!

What is a diode laser?

A diode laser uses a very bright, focused beam of blue light that generates enough heat to engrave or cut designs in materials such as wood. For the laser to cut, the material needs to absorb the light's energy, turning it into heat to burn away the design.

White and blue acrylics reflect this blue light, which is why you can't cut these colors with a diode. Clear acrylic lets most of the blue light pass right through, like a window. Dark colors absorb most wavelengths of light, which is why black acrylic cuts easily.

Advantages of diode lasers

- Affordability: Diode lasers are generally much cheaper than CO2 lasers. If you're just starting out, a diode laser is a good way to test if it's right for you.

- Smaller Size: Most diode laser, such as the xTool M1 you see above, are the size of a large printer. This makes it easy to move around and store when not in use.

- Low Maintenance: Other than cleaning the lens and cutting bed periodically, a diode laser requires less maintenance than a CO2 laser.

- Finer Engraving: The smaller beam spot size of a diode laser allows for more intricate and detailed engravings.

- Portability: Small, lightweight diode lasers such as the xTool F1 are designed to be portable, so you can take it with you to craft shows for instant personalization on products.

Disadvantages of diode lasers

- Limited Material Cutting: Diode lasers generally can't cut through thicker materials or certain colors of acrylic.

- Smaller bed size: Most diode lasers have a smaller work area than their CO2 counterparts, which can limit the types of projects you can create.

- Poor fume extraction: Open bed diode laser cutters may be less expensive, but they must be used in a well ventilated area to dissipate the fumes that are created. Enclosed systems allow smoke to be vented out a window, but the internal fans can be underpowered.

- Slow: The less power your diode has, the slower it will cut and engrave. That little dice box below took almost two hours to engrave and cut on the 10W xTool M1.

What is a CO2 laser?

CO2 lasers channel a current through a gas-filled tube, predominantly consisting of carbon dioxide. Water around the laser tube cools the system. A focused, intense light beam bounces off a series of mirrors and passes through a lens to slice through the material.

Advantages of CO2 lasers

- Power: CO2 lasers boast higher wattage than diode lasers which allow for deeper cuts and faster processing of materials.

- Speed: When speed is of the essence, CO2 lasers outshine their diode counterparts. They can swiftly slice through materials with a level of efficiency that diode lasers can't match, making them ideal for high-volume projects.

- Size: The working area of a CO2 laser is typically larger than a diode, allowing you to create larger projects.

- Thicker Materials: CO2 lasers cut through thicker materials in a single pass.

- Material Versatility: CO2 lasers can cut and engrave a huge range of materials, including clear, blue and white acrylic.

Disadvantages of CO2 lasers

- Cost: CO2 lasers are generally more expensive to purchase and maintain than diode lasers.

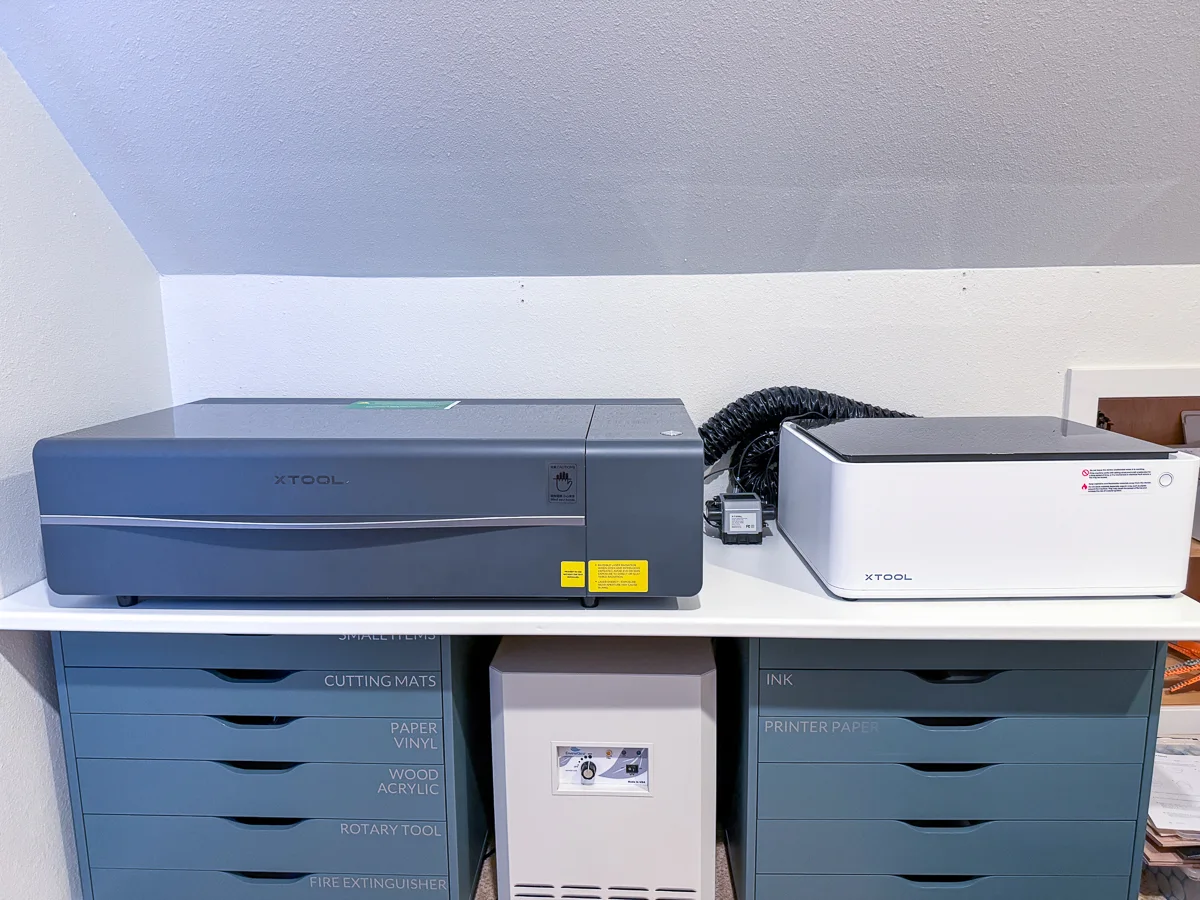

- Size: While a larger working area may be a good thing, it also takes up more space. CO2 lasers are also much heavier than their diode counterparts, making them more difficult to move around.

- Maintenance: CO2 lasers require more maintenance, including cleaning and aligning the mirrors periodically.

- Lifespan: CO2 lasers average between 5,000 and 8,000 working hours before you may need to replace parts. By dialing in the right settings with a laser test cut card, you can avoid running the machine at full power and extend the lifespan.

Selecting the right laser for your needs

Deciding between a diode and a CO2 laser for your engraving or cutting needs comes down to aligning your projects with the capabilities of the machine. Your production scale, material choices, and budget will dictate the best path forward for you.

I've used both the xTool P2 and the M1 extensively, and have a good feel for where each one shines. Let's take a look at some of these pros and cons in real life scenarios, so you can decide which type is right for you.

Working area

The xTool P2 has a working area of 23.6"×12", versus the 15"x12" of the xTool M1. The bed is even larger, with adjustable slats that fit into grooves in the front and back. You can move the slats around to prevent smaller pieces from falling through, and there's an optional honeycomb panel for really tiny cuts.

You can cut even larger materials with the optional riser base, which allows you to open up the front and back to pass a board through. The conveyor system automatically moves the board back and forth to cut and engrave items up to 8 feet long!

However, if you're planning to only cut small items like jewelry or Christmas ornaments, a diode might be all you need.

Speed

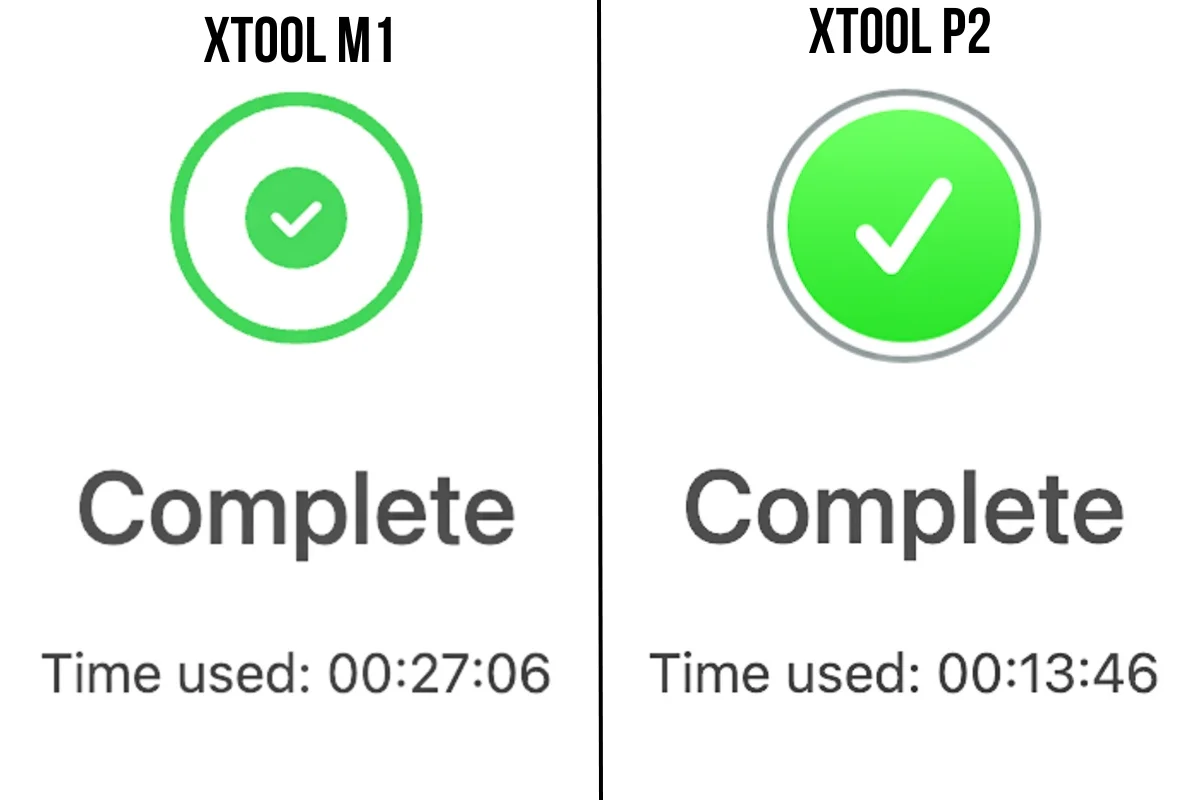

With greater power comes greater speed. My 55W CO2 laser is more powerful than the 10W diode laser, so it can cut and engrave much faster.

To put this to the test, I used the same file on both machines. I ran test grids on both machines to find comparable engrave settings. Both are cut at the fastest speed that goes all the way through 3mm basswood plywood.

What a difference! The P2 is twice as fast as the M1 when completing both engraving and cutting of the same file.

If you're batching out lots of projects to sell online or at craft shows, a CO2 laser may be the better choice. Even if you're using your laser as a hobby, waiting half an hour for a small job like this one to finish can get annoying. I find that I'm using the CO2 laser way more often than the diode simply because it's faster.

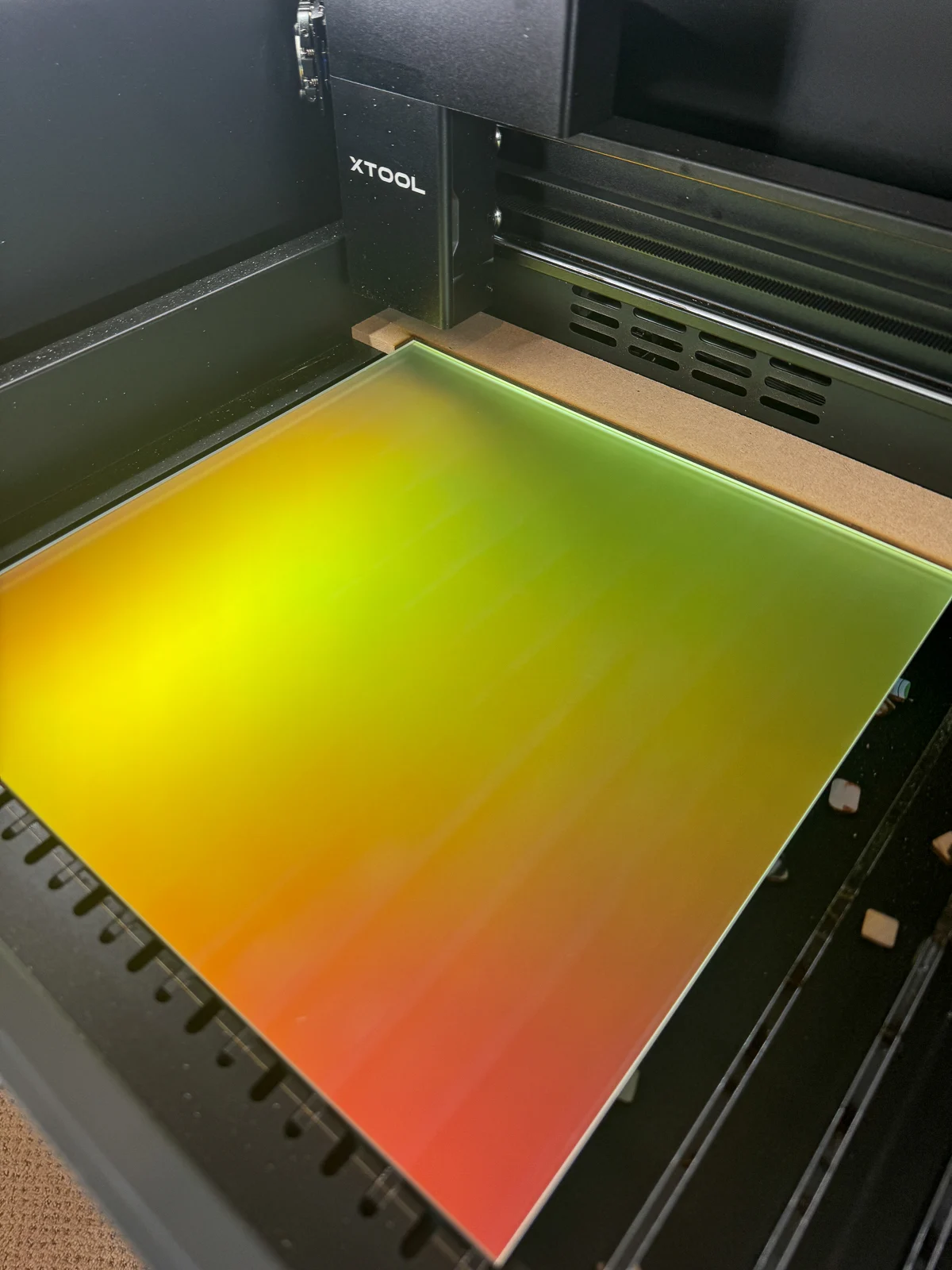

Cutting acrylic

One task that CO2 lasers can do that diode lasers can't is cut clear, white and blue acrylic. This includes iridescent acrylic like the one I used for these giant snowflakes, and mirrored acrylic like the vase for my laser cut rose bouquet.

But if you're only planning to cut thin plywood or black acrylic for small items, you can save a lot of money and stick with a diode laser.

You can also get creative using thin clear flex material, like the stuff I used for these DIY acrylic bookmarks and DIY night light covers, which I cut on the xTool M1 Ultra diode laser!

Which should you choose?

If you're thinking of getting a laser just for personal crafting purposes, I would recommend starting with a diode machine. The lower price point makes it easier to get started and see if it's a good fit. There's plenty of fun projects you can make!

But if you want to start a laser business or Etsy shop, time is money! CO2 lasers allow you to batch out more products in a shorter amount of time. You can also expand your product line with unique acrylic colors or patterns that catch a customer's eye.

So, which laser are you planning to get? Let me know in the comments below!

Check out these laser project ideas!