Learn how to cut melamine without chipping. Essential tips on tools, techniques, and preparation for perfect, clean cuts in your projects.

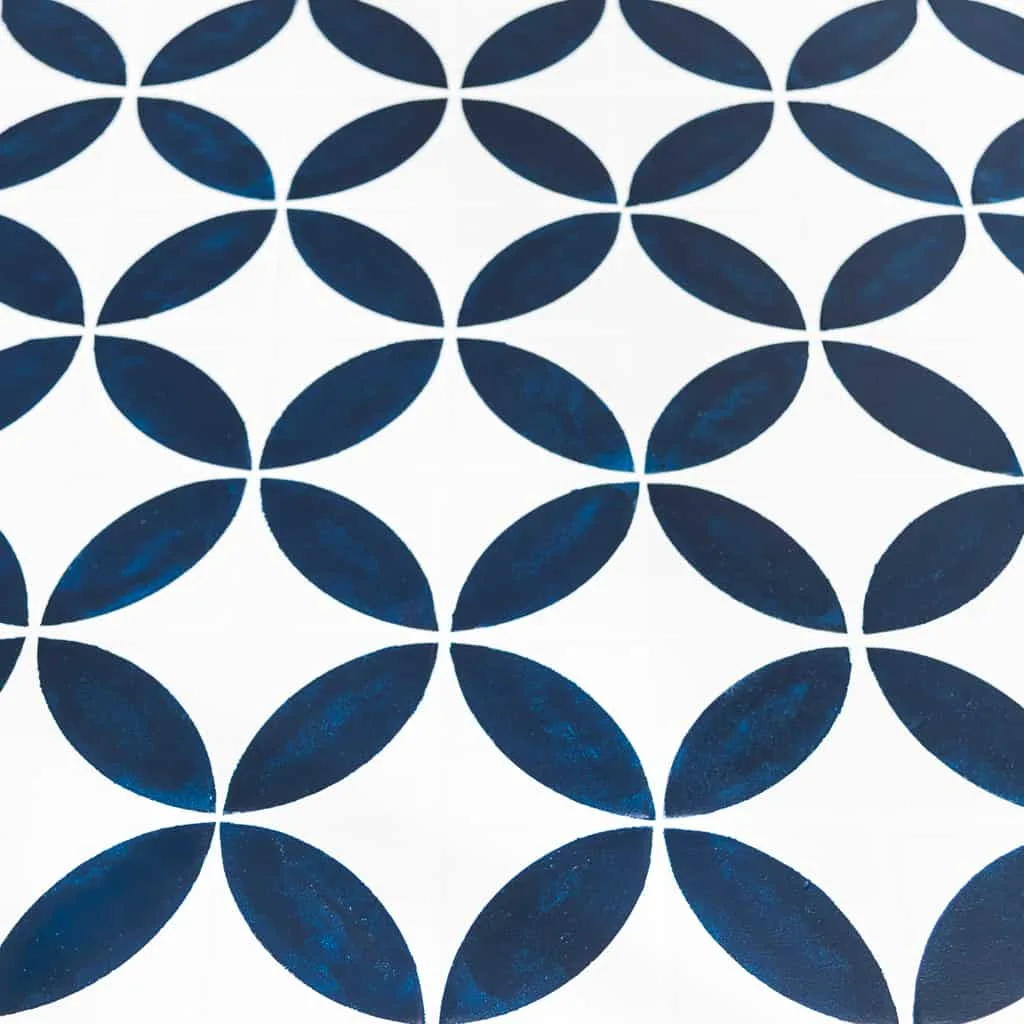

Melamine is my go-to material when I want to avoid painting or need a slick surface. Known for its durability and sleek finish, melamine is a popular choice for cabinetry and shelving.

But melamine has a major weakness. It tends to chip during cutting or drilling, which can turn an otherwise perfect project into a frustrating challenge.

In this article, I'm sharing all my tips and tricks for getting clean, chip-free cuts and holes in melamine!

This post contains affiliate links for your convenience. Purchases made through these links may earn me a small commission at no additional cost to you. Please visit my disclosures page for more information.

What is melamine?

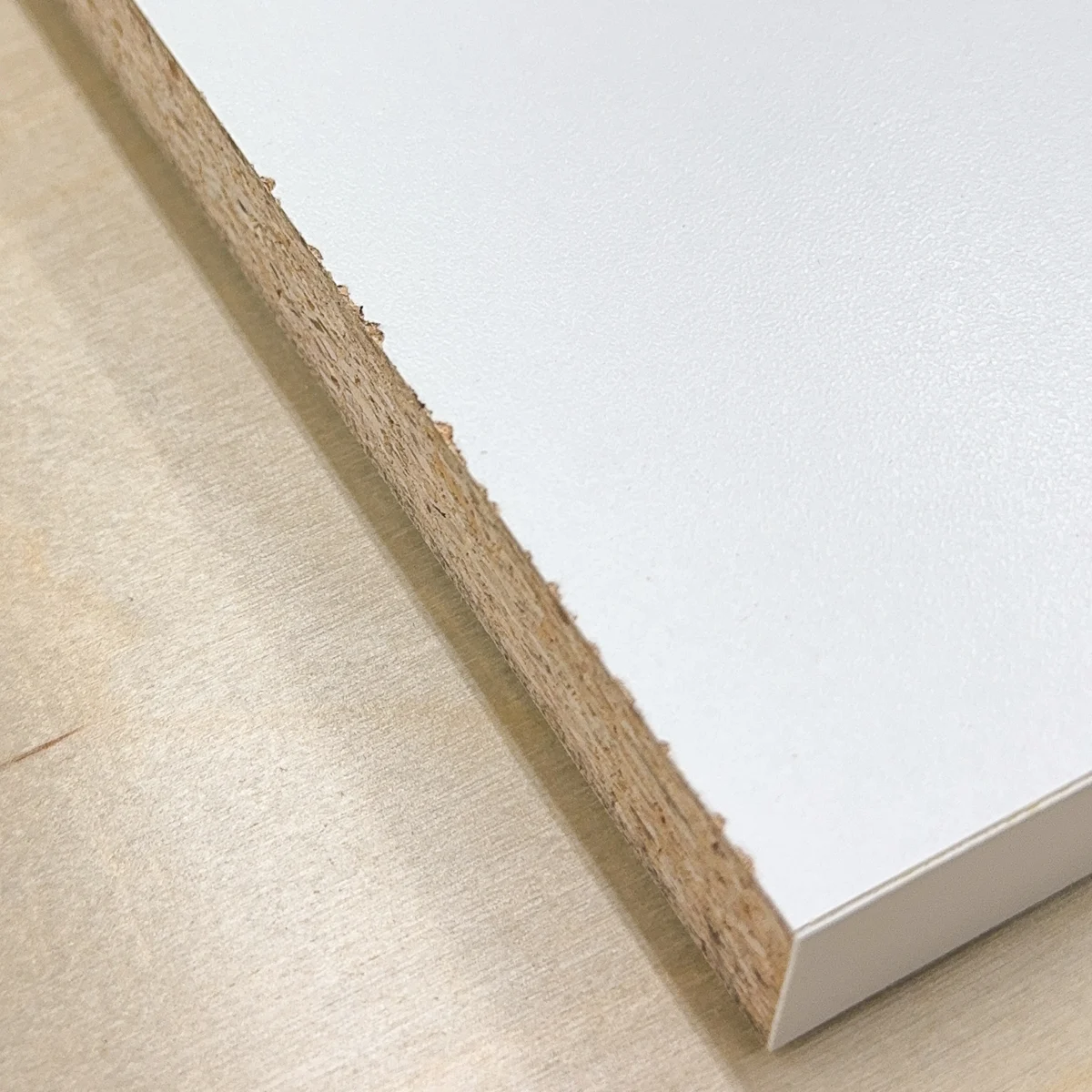

Melamine is a type of laminate bonded to a substrate, such as particleboard or MDF, using heat and pressure. This process creates a smooth, hard surface that's resistant to scratches and stains.

However, this makes melamine prone to chipping when cut improperly. The outer layer is thin and brittle, which can easily tear away at the edge.

While it is possible to paint melamine, if you're building a project from scratch and want a specific color, you're better off using plywood instead.

Preparing melamine for cutting

Before you dive into cutting melamine, proper preparation is crucial. This not only makes the cutting process smoother but also reduces the likelihood of chipping.

Secure the board

Clamp down your melamine board to a stable surface. This prevents movement during cutting, which is a common cause of chipping.

If you don't want to cut into your work surface, place a sacrificial piece of thin plywood or MDF under the melamine. This support reduces tear-out on the bottom side as the blade exits the material when cut with a circular saw.

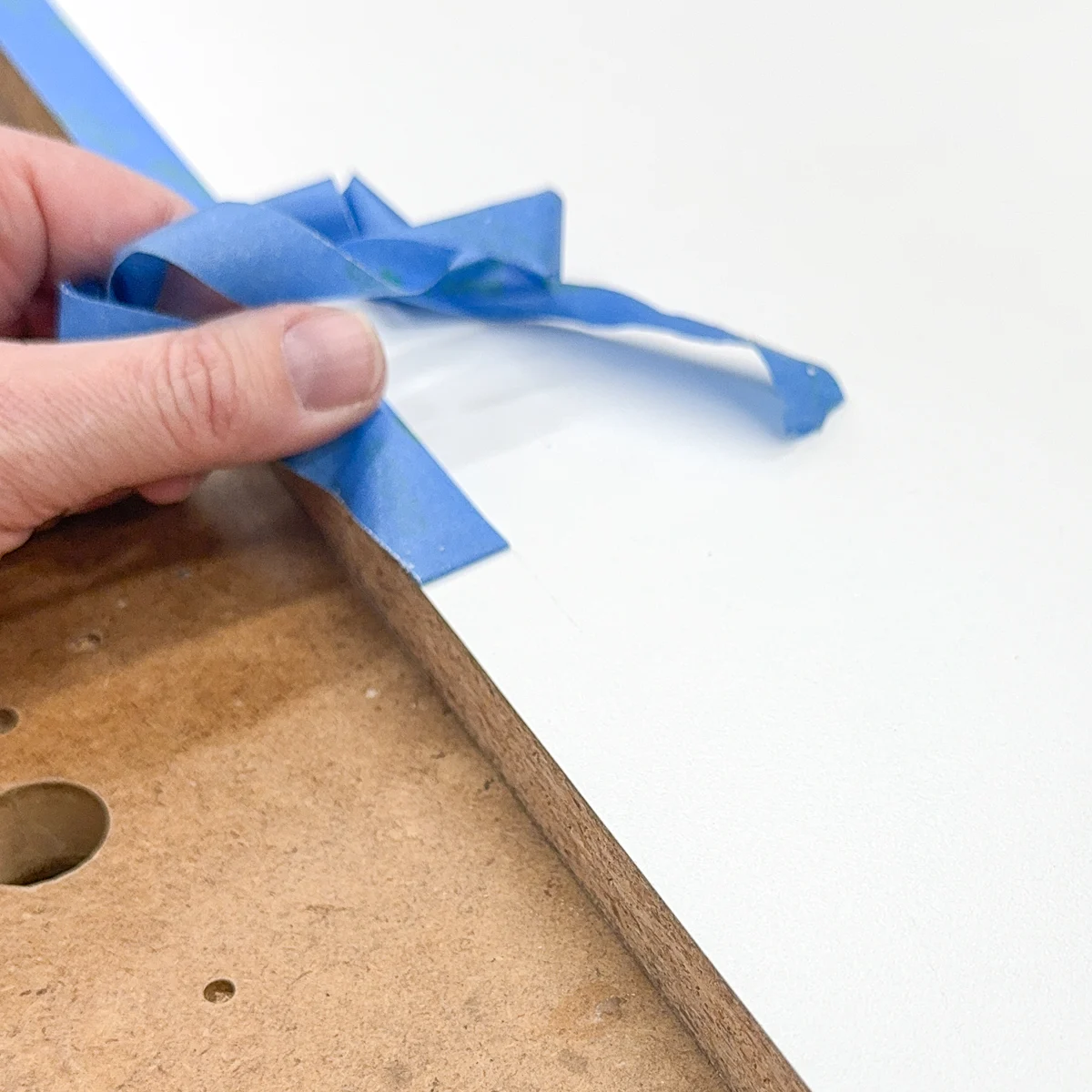

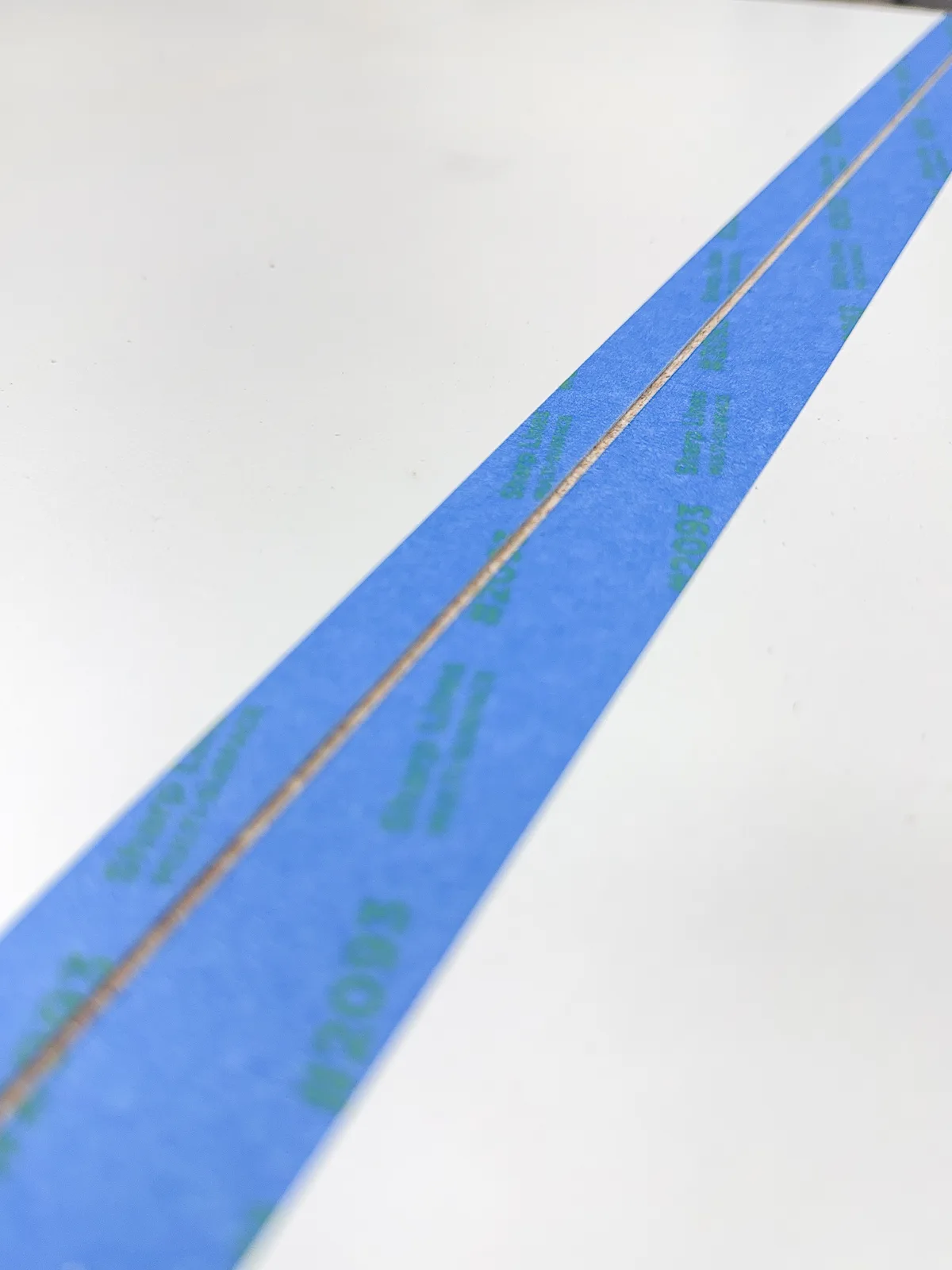

Use tape along the cut line

Masking tape or painter's tape is a great way to hold melamine together when cutting or drilling. The tape should be wide enough to fully cover both sides of the cut line, and sticky enough to prevent peeling up on the slick surface.

Once you've marked your cut line on the melamine, apply the tape directly over it. Ensure the tape is smooth and free of bubbles or wrinkles, and press it down firmly. Then redraw the cut line on top of the tape.

After making the cut, peel back the tape and see how it looks. This melamine edge turned out perfect!

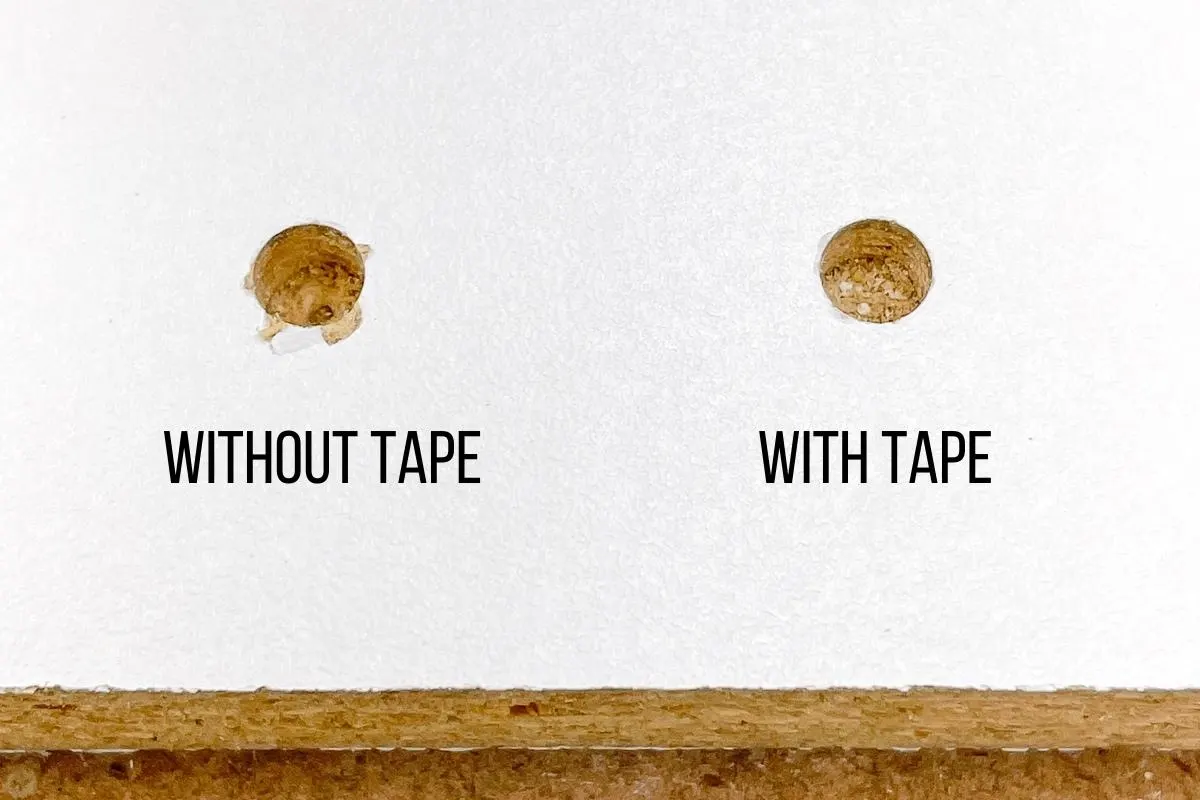

Here you can see the difference when using tape to drill shelf pin holes in melamine. It's totally worth the extra effort!

Choose the right blade

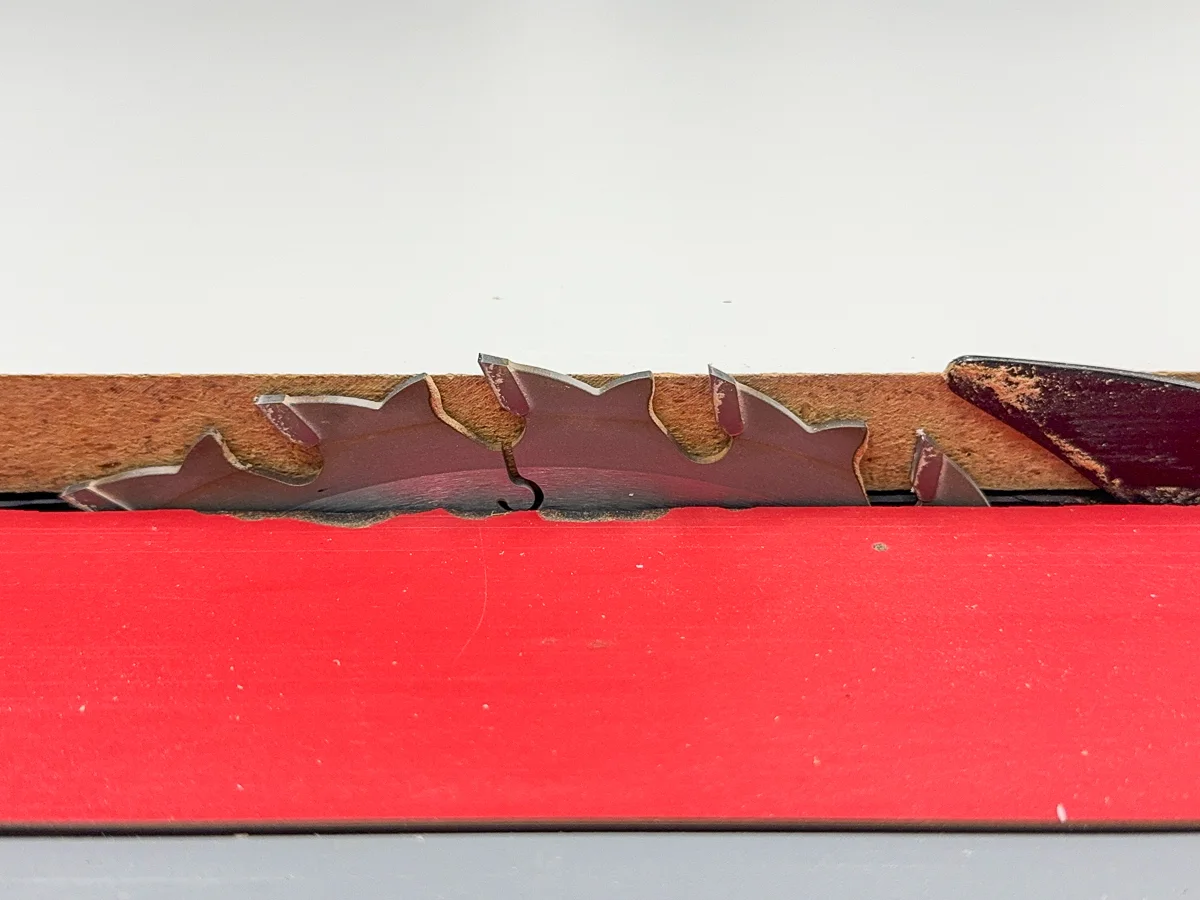

Not just any blade will do. For melamine, use a blade with a high tooth count — ideally 60 teeth or more for a circular saw and 80 teeth or more for a table saw.

There are specially designed blades for melamine and laminate surfaces that minimize the vibrations that cause chip out. This one is ideal for double sided melamine cut on the table saw, while this one is sized for smaller circular saws.

For a jigsaw, use a fine tooth blade that cuts on the downstroke. Turn off any oscillating features, and use a splinter guard if available.

Melamine cutting techniques

Now that we have everything ready to go, it's time to cut! Here are the steps and tips to ensure a chip-free cut in melamine.

Protect the "good" side

Take a look at your board and see if there's a "good" side without any scratches or damage. That should be the more visible side on your finished project.

If the outside of your box will be hidden, like in a bank of cabinets, you'll want the good side on the inside. If the inside will be hidden by drawers or doors, make sure to preserve the outside.

Wherever the blade enters the wood will get the cleaner cut. By positioning the board with the good side facing into the blade, you can minimize damage to the coating.

If you're using a table saw or track saw, the blade cuts from beneath the material. So you should keep the front face down.

Make a scoring cut first

A scoring cut is a shallow cut that doesn't go all the way through the board. This technique can be helpful if you want to ensure that both sides of the melamine are chip-free.

Adjust the blade height on your saw so that it's just deep enough to cut through the melamine's top layer, about 1/16 of an inch. The FS side of the scale is for use with the track on the Festool saws.

Cut a shallow groove first, then make the same cut all the way through. You won't need to move anything if you're using a track saw. You can use the same fence settings on a table saw and flip it over between cuts.

Adjust the blade height

Adjust the blade height so that it's just above the thickness of the melamine board. This minimizes chipping by reducing blade contact with the surface.

Chipping occurs when the teeth catch on the edge of the melamine as it passes the blade. By reducing the number of teeth that are in contact with the board, you minimize the damage.

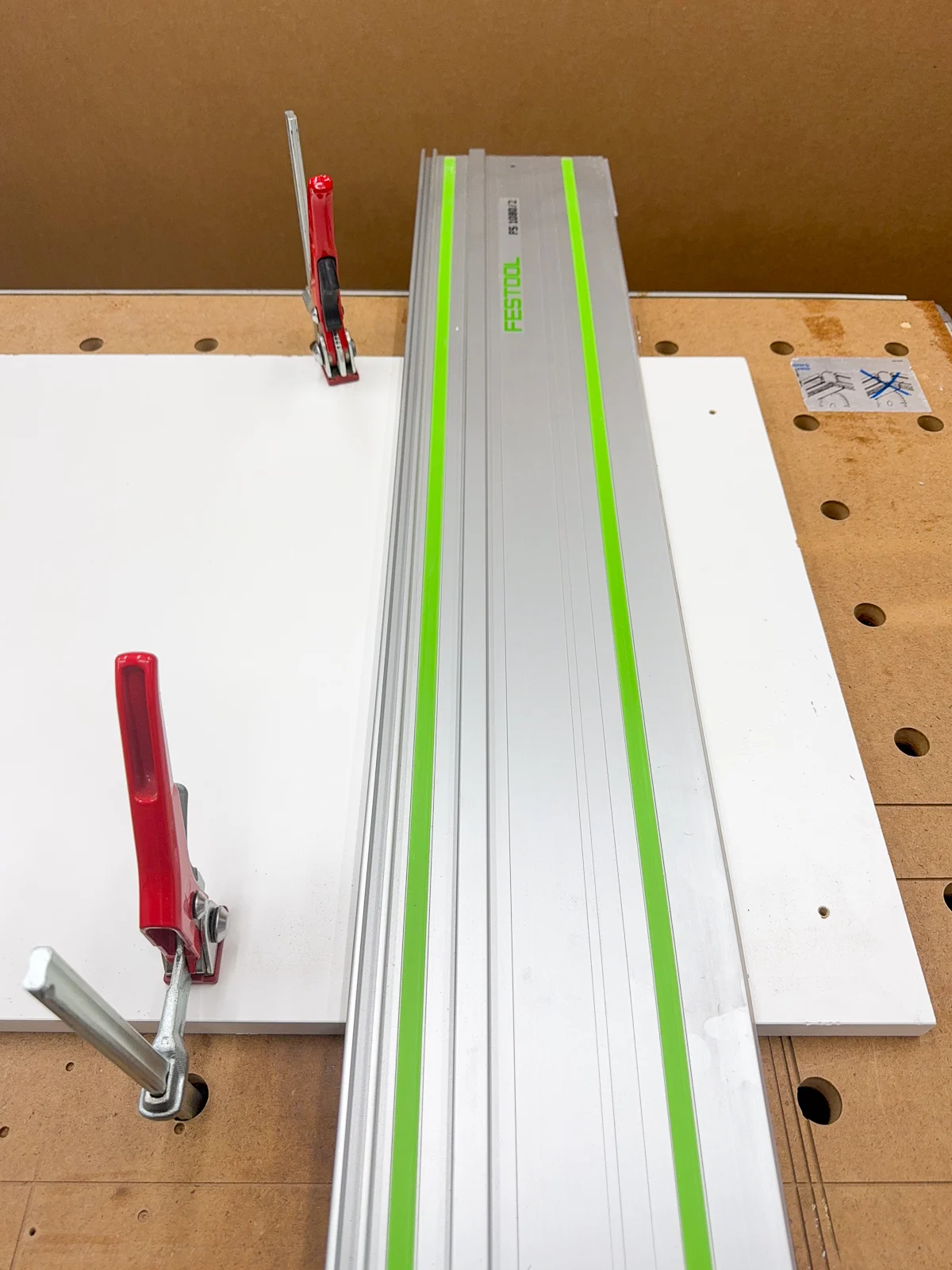

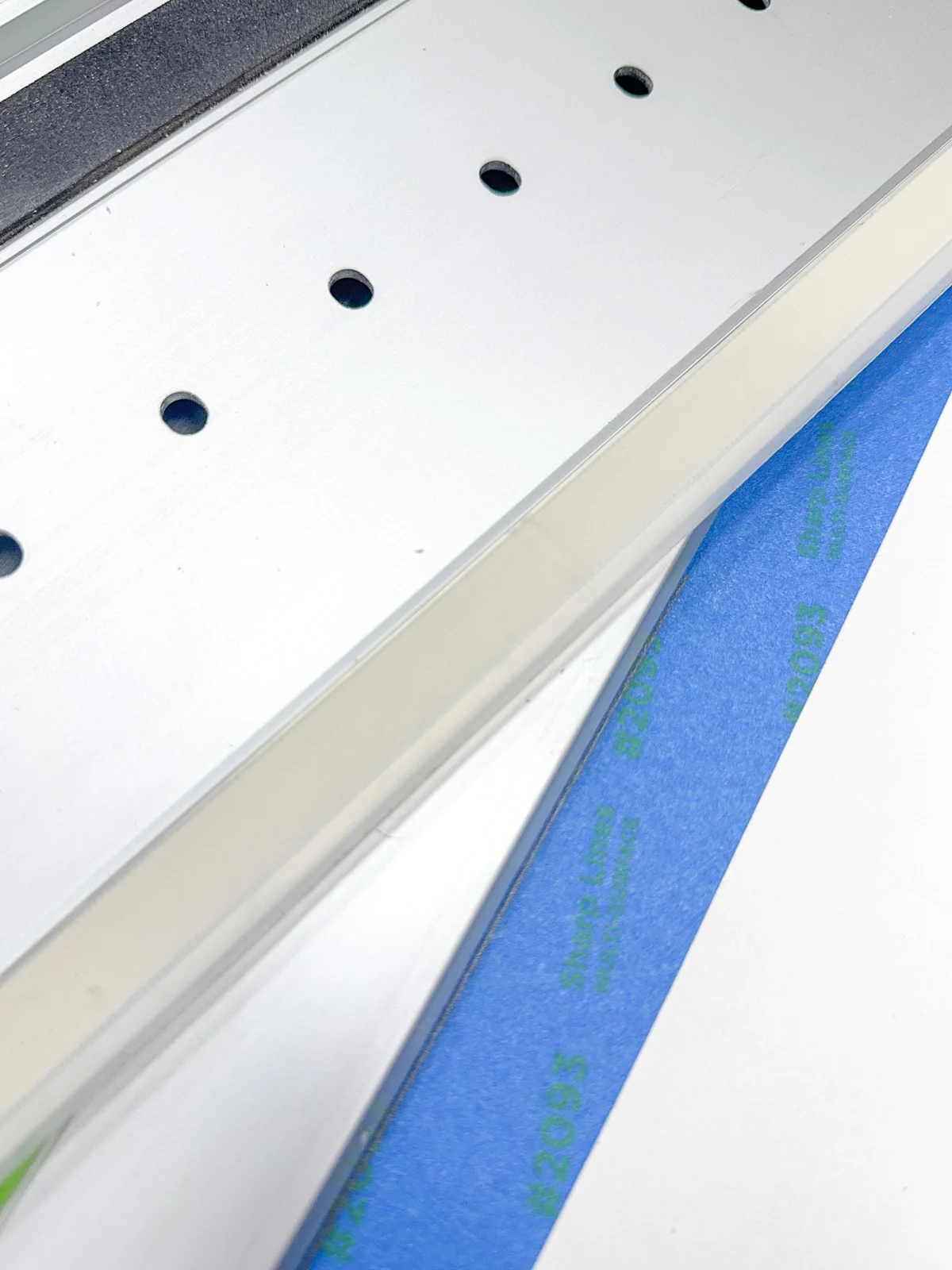

Use a track with handheld saws

I often choose a track saw over a table saw for cutting melamine and other sheet goods. I don't have the space to cut larger sheets on the table saw, and track saw cuts are typically cleaner.

The track has a rubber splinter guard on the edge, which applies pressure along the cut line and holds the fibers in place. It also reduces vibrations from the saw, and keeps your cut straight.

Make sure that the "keep" side of the cut line is under the track when lining it up. Apply even pressure and speed throughout the cut. Check out that perfect edge on the top of the waste side too!

You can buy tracks for a circular saw as well, so you don't necessarily need to buy an expensive track saw. The Kreg circular saw track has a similar splinter guard to protect that cut edge.

Finishing melamine edges

Now that you made a clean cut, you're still left with those ugly particleboard edges (and maybe a few tiny chips too). Luckily, you can cover them up for a flawless finish!

Melamine edge banding

You can hide that exposed particleboard with melamine edge banding. The process is the same as applying plywood edge banding. Basically, you just iron it on and trim off the excess with an edge banding tool.

You only need to apply edge banding to the areas that will be seen in the finished project. Typically, that's just the front edge of the cabinet and shelves.

Melamine touch up paint

Even after taking all the precautions above, chips can still happen. Ugh!

But don't worry! There's an easy fix that will cover up those imperfections. A paint pen!

There are special touch up markers that are formulated to match melamine, but I have an assortment of acrylic paint pens that works great too. Just color in the chipped sections and it almost disappears!

For bigger chips, or for damaged areas, you can use a special filler made for melamine. It bonds with the surrounding laminate for a stronger repair that also brings the surface flush.

Now that you know how to cut melamine without chipping, you can build that project without worrying about unsightly damage!

Check out these other helpful home improvement tips!