This guide teaches you everything about plywood! What's the difference between types of plywood, or what to look for when buying plywood.

Many of my woodworking plans call for plywood, and I get a lot of questions from readers asking about the types of plywood I use. The answer is usually ... it depends!

The type of plywood used on garage storage shelves will be very different than the kind used on a kids bookshelf or a pantry cabinet.

This guide will hopefully take some of the mystery out of this versatile building material. I'll teach you everything you need to know about plywood and other sheet goods!

This post contains affiliate links for your convenience. Purchases made through these links may earn me a small commission at no additional cost to you. Please visit my disclosures page for more information.

What is plywood?

Plywood is a composite material, which simply means that it is made up of multiple layers of wood veneer glued together to make one large sheet. No matter what you’re building, whether it's a tree house, or an actual house, there is a good chance you will need some plywood to get the job done.

When you glue lots of thin sheets of wood together, with the grain oriented perpendicular to the previous layer, the finished product is stronger and more flexible than if you were using solid wood. Plus, it's an easier and more cost effective way to cover a larger area.

How big is a sheet of plywood?

Plywood is typically sold in four foot by eight foot sheets. You can also find smaller sizes, called "project panels" that are already cut down into more manageable sizes. These can range anywhere from little 1 foot square pieces all the way to 2' x 8' half sheets in a variety of thicknesses. Look for these project panels in vertical cubbies near the plywood section at your local home improvement store!

How is plywood made?

First, a log is soaked in water, then it is loaded onto a big machine which shaves the log down into thin sheets - like peeling an apple. These sheets are called “veneer” and they are glued together in opposing directions and pressed to create plywood.

This video shows the process of how plywood is made, which is actually kinda cool!

Number of plies in plywood

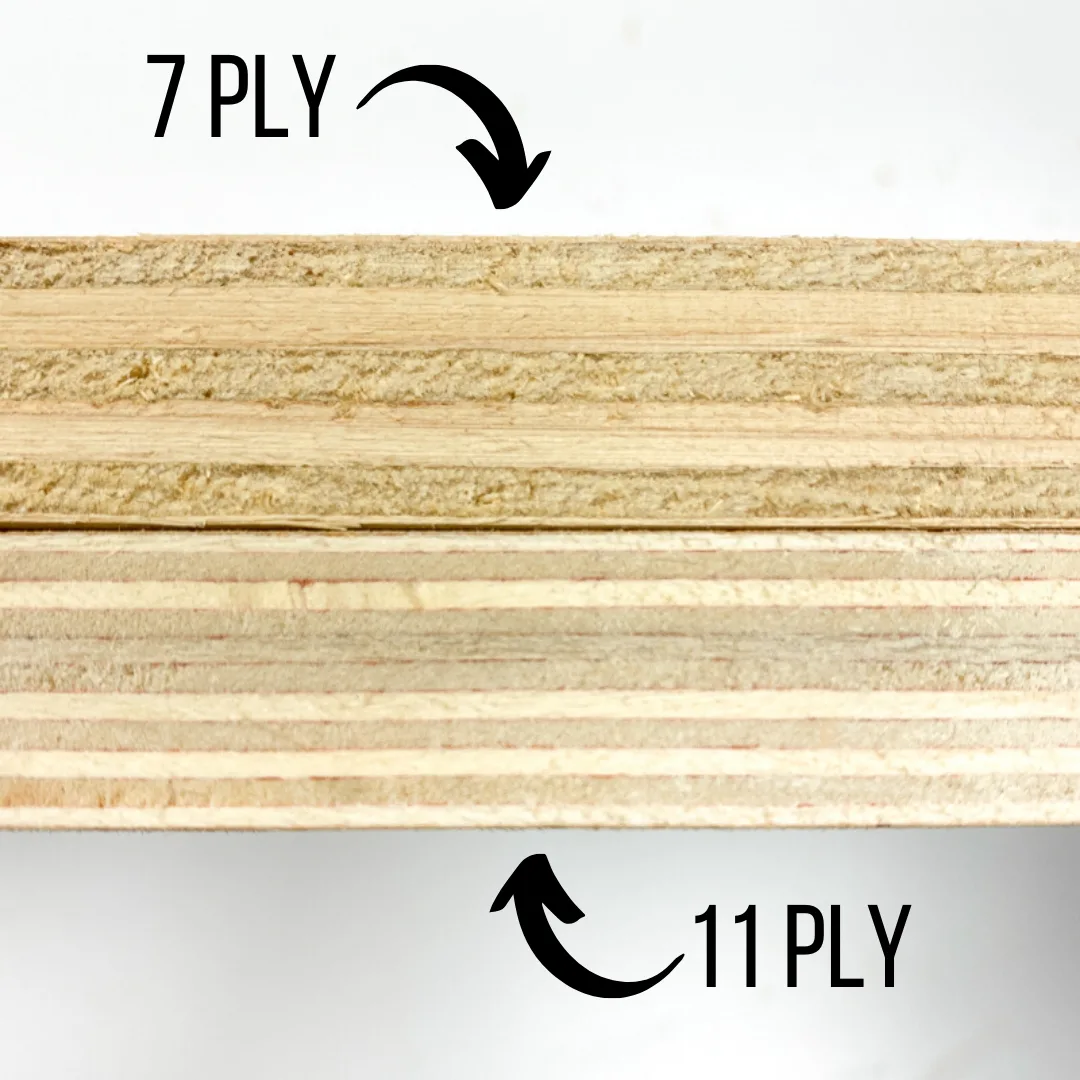

When I first started woodworking, I figured that the number of plies (or layers) in the plywood determines how thick the sheet is. It blew my mind to find out that 7, 9, 11 and 13 ply sheets can all be ¾" thick! Whaaaaat?!?

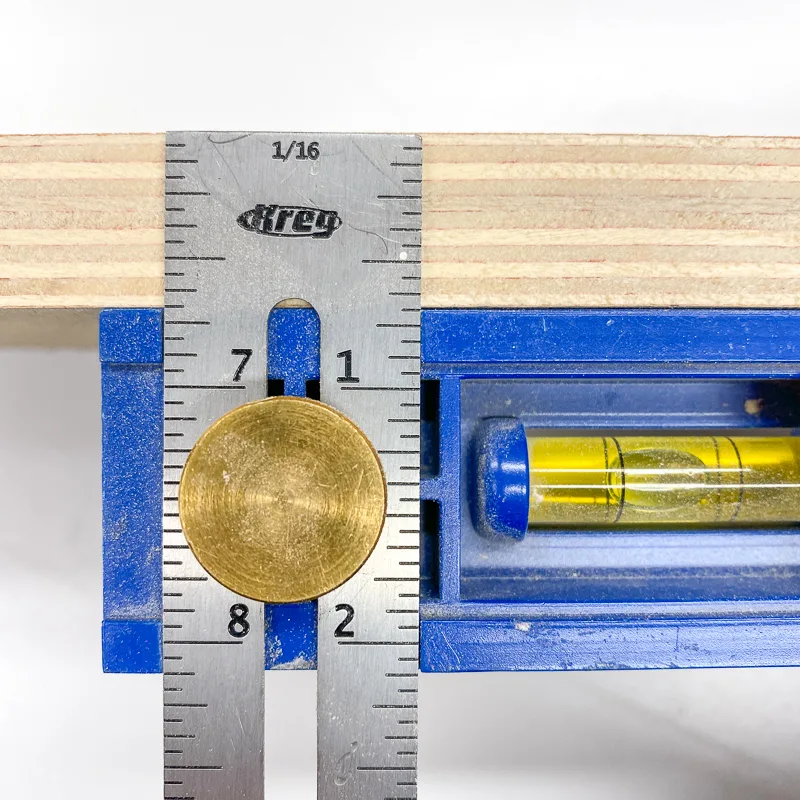

And to make it even more confusing, most plywood isn't actually ¾" thick (or ½" or ¼"), but slightly smaller! No wonder some of my projects weren't turning out quite right!

So if you're choosing ¾" plywood for a project, why go for the more expensive 11 ply sheet over a cheaper 7 ply? They both have the same thickness of wood, so they should be the same, right? Nope!

A sheet of plywood with 11 plies will have very thin veneers, with wood glue in between each layer. Each of those wood layers is less than 1/16" thick! More layers = more stability.

Notice how the top and bottom layers of the 7 ply sheet is super thin, while the rest are pretty thick? Now imagine sanding that piece of plywood, and how easy it would be to sand through to the next layer. Ugh! The 11-ply sheet has more consistent layers, and a thicker top and bottom layer that's harder to sand through.

When you cut a piece of 11 ply plywood, there's usually very little chipping because the wood glue bonds the thinner layers together tighter. On cheaper 7 ply plywood, big chunks can break off of the cut edge and weaken the joint between two pieces.

Do you need to buy expensive Baltic birch 11-ply plywood for your first basic project? Of course not! I'll only use the good stuff on the nicest furniture pieces that rely on precision accuracy without any bowing.

Plywood grades

The grade of your plywood refers to the quality and appearance of the wood, particularly on the outside layers you can see. The higher the grade, the more flawless the surface will be. Think about how your project will be finished before choosing the plywood.

C/D grade plywood

I used inexpensive C/D grade structural plywood for my son's DIY climbing wall, because the surface would be textured with sand and painted. There were knots and holes in the outer layers, but on a climbing wall, those are features! 😉

This grade is typically used as subfloor plywood, and is covered up with something else to make it look nice. It's sometimes called sheathing plywood.

B grade plywood

For painted projects that will have both sides of the boards showing, like this entryway storage bench, I'll use B grade plywood. The holes in the outside layers are patched, and the paint will cover up any knots or imperfections for a flawless finish.

A grade plywood

Grade A plywood will have a perfectly smooth surface which is good for when you want to stain your project or leave it natural. There will be no knots or imperfections, and both sides will be flawless. This is the most expensive type of plywood, and is usually referred to as cabinet grade plywood.

I used prefinished hardwood plywood to build my kitchen cabinets. It had a flawless wood veneer on both sides, and a clear finish that protects the wood from heavy use.

2 letter grade plywood

Sometimes, you will see plywood that has two letter grades. For example, it might say A - B. This means that one side of the sheet is grade A and the other side is grade B. So one side will be perfectly smooth and the other side will have patched knot holes.

This comes in handy because A - B will be cheaper than straight A. Often it won't matter for your project because people will only be able to see one side of the wood anyway.

I used A-B plywood on my sliding barn door because one side was covered up with wood shims while the other side was just stained. I used the better A side for the back facing into the bathroom, and the B side for the shims.

Types of plywood

There are tons of different types of plywood and the selection can be overwhelming. I cover the main ones below, but you can always ask the employees at your local lumber yard what they would recommend.

Structural plywood

Structural plywood is used for roof sheathing or subfloors, and will probably be covered up with something more decorative. Its primary goal is to be as strong as possible. Structural plywood comes in both C and D grades, but no higher.

It will be less expensive than other options, because it's a softwood plywood that has knots and imperfections. You can use it for furniture making, but will take a lot more work to make it look nice.

Lumber core plywood

All those thin veneer layers take a lot of effort to glue together, which can increase the cost. For thicker decorative plywood without the huge price tag, you may want to consider lumber core plywood.

This type of plywood has a thick core of solid wood, sandwiched between thin wood veneers like traditional plywood. The core is typically made of an inexpensive softwood like Douglas fir, with ornamental wood on the outside layers.

Sanded plywood

You may see the term "sanded plywood" when shopping for plywood sheets for your project. These are typically softwood plywood that has been sanded smooth at the factory, which can save you a step when building furniture.

Softwood plywood or sanded plywood is usually cheaper, and is made out of pine, fir or spruce. It's more likely to dent or scratch, so it shouldn't be used on tabletops or desks that get a lot of heavy use.

Furniture or cabinet grade plywood

Cabinet grade is typically hardwood plywood, and is sometimes called decorative plywood because the outer layers are a more attractive wood species like maple or walnut.

Hardwood plywood may have a different species for the inner core, or even a solid wood core, which can save you money. Both types can be found in grades A-D.

Exterior plywood

Exterior plywood is specifically made to withstand the elements. The veneers are held together with water resistant glue, so the layers don't peel apart. It's typically used as exterior sheathing plywood on the outside of a house, such as roof decking.

Also, it usually has a higher number of veneer layers than interior plywood. This is so that there is more glue in the plywood, which makes the sheet more resistant to water and mildew. However, you still need to apply a water resistant coating, like exterior paint, to protect the wood from rotting.

Marine plywood

Marine plywood is one of the highest grades out there (aircraft plywood is even higher - no pun intended!) Every knot hole in each layer of veneer is filled, and water resistant exterior glue is used so the layers won't separate. This is why I recommend waterproof wood glue on all my outdoor furniture projects as well!

Not only does marine plywood use weather resistant adhesive, but it can also be made with rot resistant wood. Tropical plywood can be used for outdoor furniture because of its weather resistant properties.

Non-plywood sheet goods

While the sheet goods below aren't technically types of plywood, they can be an adequate substitute in some cases. However, they are not nearly as strong as plywood. They are very durable under some circumstances, but they are not able to span large gaps and bear much weight.

Medium-density fiberboard (MDF)

MDF is one of the most common plywood alternatives. It is made by mixing ground up wood fibers and sawdust with glue and then pressing this paste into a sheet. Sometimes the outside is covered with a thin layer of melamine so it doesn't need to be finished after assembly.

The major benefit of this material is the perfection of the finished surface. Since it's completely fabricated, you don’t have to worry about any knots or imperfections in your piece. However, there's no wood grain, which can be a problem if you want to stain your finished project.

MDF is very easy to cut and paint. However, it is not able to bear a lot of stress, so you may end up with cracks or splits if you don't predrill holes or support the weight properly.

Hardboard

Hardboard is very similar to MDF with the major difference being that it is harder and thinner. It is made in the same way as MDF, but is much more tightly compacted. It's commonly used as a backing on cabinets and bookcases.

I used a thin, coated hardboard, similar to a whiteboard, to cover over the wood paneling of my workshop. Now I can write notes about the type of wood stored on my lumber rack, or cut lists for my latest project!

Particleboard

Particleboard is the cheapest plywood alternative. This is because it is often recycled material. It is made from small wood splinters which are scraps from the large saw mills which fabricate other wood products.

Particleboard may be cheaper than plywood, but it is the least durable of all the materials we have discussed. This is the stuff IKEA furniture is made of. It's easy to break, and will swell if it gets wet.

The only time I'll use particleboard is for shop projects like this cordless drill storage rack. It's not pretty to look at, but it used up some pieces the previous owner left behind!

Oriented-Strand Board (OSB)

OSB is a product somewhat similar to particleboard, but it is made from large thin chips and slivers rather than little splinters. Since the pieces it's made of are more robust, the material itself is also stronger than particleboard.

You can read more about the differences between OSB and plywood here!

I used OSB for my storage shelves because they were going in our shed and didn't need to look pretty. It's a cheap option for covering a large area, but I would go with something nicer if you're making something you'll see all the time.

Plywood buying tips

Once you have decided what type of plywood best suits your needs, it's time to go buy it! Here are a few things to watch out for when you're selecting your wood.

The first thing to look out for when buying plywood is whether the board lays flat. If it's warped, swelling, or has waves in it, stay away! This can be a sign of water damage, or just bad quality in general. I've been known to dig down three or four layers before finally finding a good sheet.

Remember that sometimes one piece of plywood will have two grades. Take a look at both sides of the sheet before you buy it so that you don’t get any surprises later on.

Another thing to check for is clean edges with no dents. If you get a piece of plywood that has crummy edges, it will make it very hard to work with. Usually you base all your cuts off of the factory cut edge, but if that edge is beat up, your measurements will all be off!

If you can't fit a full sheet of plywood in the car, you can usually get it cut down to a more manageable size at the store. I bought my Volkswagen Tiguan specifically because the front seat folds completely flat so I can haul plywood sheets up to 2 feet wide and 8 feet long!

However, those big saws aren't particularly accurate and can leave jagged edges, so I suggest getting your plywood cut a few inches bigger than you need. That way, you can use more precise methods like a table saw, track saw or circular saw to get the exact dimensions and a cleaner cut!

I hope this article was helpful in taking some of the mystery out of the different types of plywood!

Check out these other plywood-related articles!

Claudia

Saturday 13th of June 2020

Thank you so much for this. I have been somewhat reluctant to use plywood in projects but now that I am informed I can use it with confidence! Bravo!