What's the difference between a track saw and a circular saw, and which is best for you? I'll compare these two tools to help you decide!

A track saw and a circular saw are both incredibly useful, and I've used both extensively over the course of my woodworking journey. However, depending on the jobs you need to do, one might be a better option than the other. This article will help you decide which one to buy!

This post contains affiliate links for your convenience. Purchases made through these links may earn me a small commission at no additional cost to you. Please visit my disclosures page for more information.

What's the Difference Between a Track Saw and a Circular Saw?

Here's a list of differences between the track saw and circular saw:

- Track saws are essentially circular saws that run along a track. However, track saws have several added features (scoring, full blade cover, dust collection, riving knife).

- Circular saws are much cheaper than track saws.

- Track saws are traditionally used for cutting down large sheets of plywood with a clean edge that is ready for assembly. Circular saws can leave splinters and tear out along the cut.

- With modification and jigs, you can use circular saws similarly to track saws.

- You can use track saws without their tracks. Also, if needed, you can buy track extensions to make extra long cuts.

What is a Track Saw?

A track saw is essentially a circular saw that runs along a track. This track makes it super easy to get perfectly straight cuts. Just line up the edge of the track with your cut line and start cutting! Honestly, once I bought a track saw, I gave away my circular saw and never looked back!

A track saw can be battery-powered or corded. I've had both versions, and I prefer the battery powered one. I've had a few instances where the cord got caught on the end of the track, pulling it out of alignment and ruining the cut.

Here are several features that come standard with most track saws:

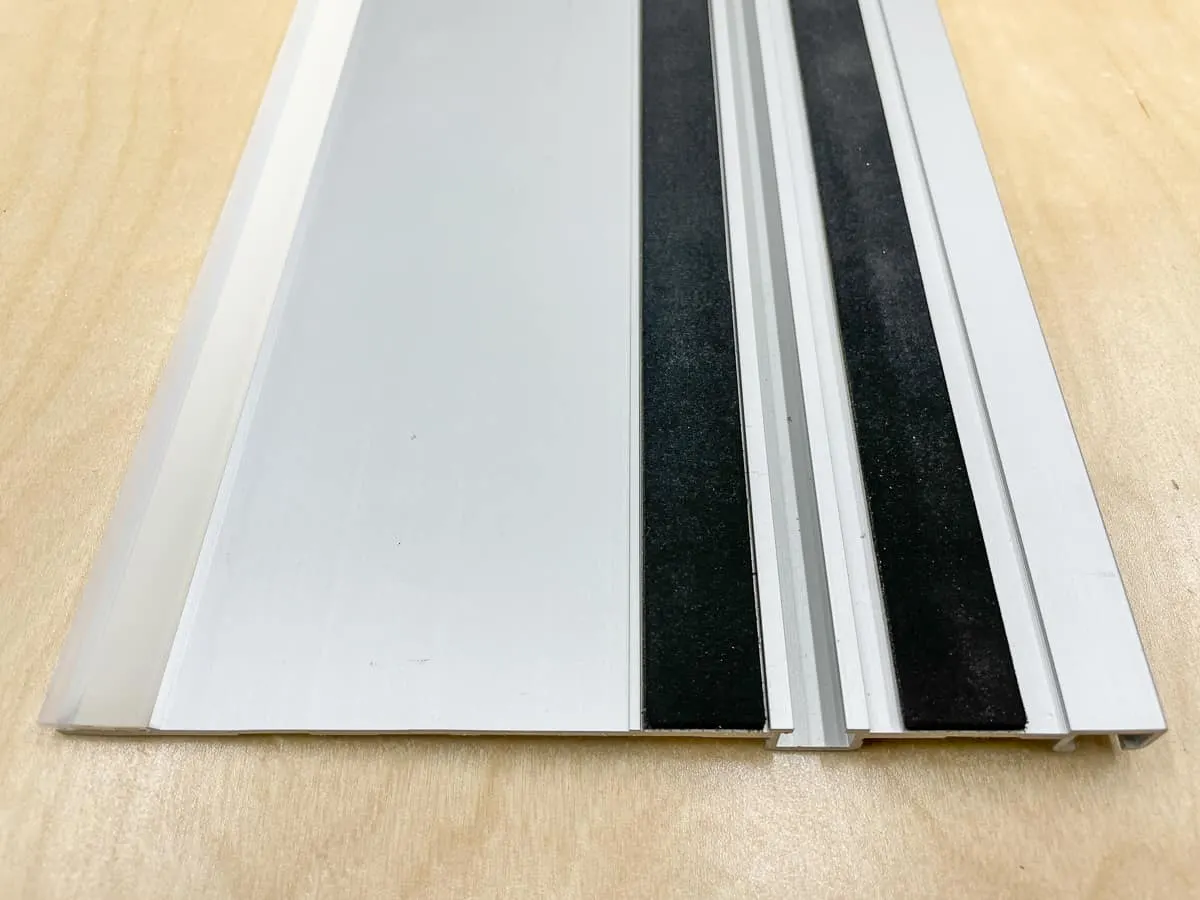

- Track - The track guides the saw in a straight line. It has a grippy but non-marring underside to keep the track in place without clamps in the way. However, I sometimes use these Bessey track saw clamps to lock the track down tight so I don't mess up a crucial cut.

- Splinter guard - The edge of the track has a clear rubber material attached, that is perfectly sized to your particular saw. This allows you to align the track with your marks for exact placement, and also prevents tear out.

- Vacuum or dust bag - Most track saws have a port to attach a shop vac or a dust bag, keeping your workspace clean. The enclosed blade cover allows for much better dust collection.

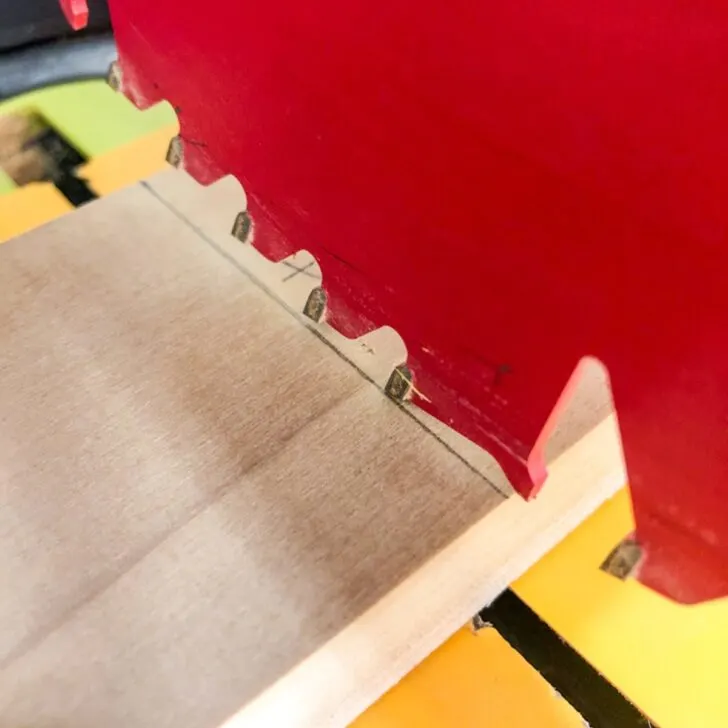

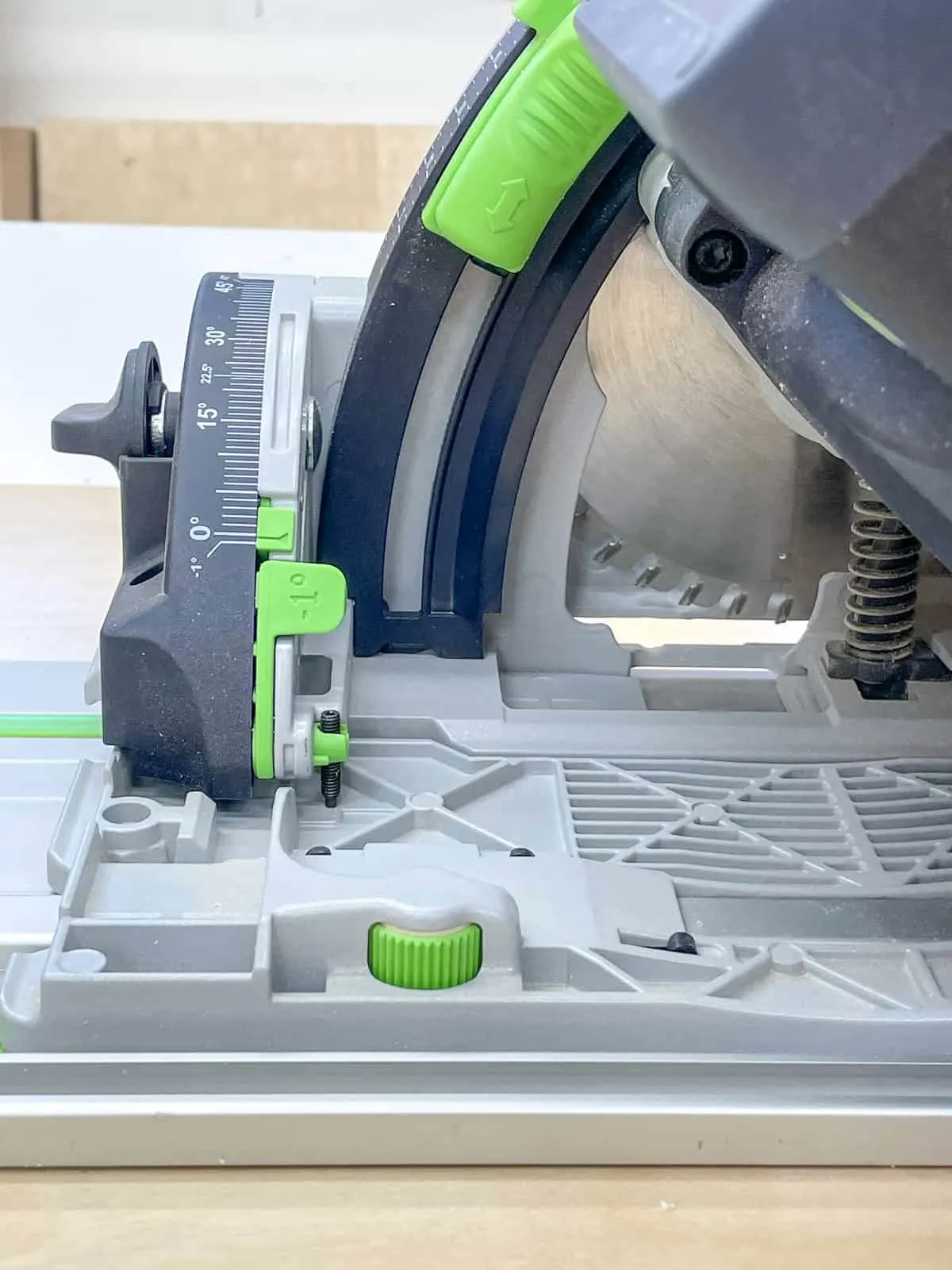

- Blade - The blade of a track saw is usually around 6.5 inches, just slightly smaller than a traditional circular saw. Like a table saw, some track saws come with a riving knife. This knife follows the blade and prevents the saw from kicking back and causing injury.

- Depth Stop - You should always set the depth of the cut to just below the surface of the wood you're cutting when making a through cut. But you can also cut grooves that don't go all the way through the board by adjusting the blade to a shallower depth.

When Should I Use a Track Saw?

Use a track saw when you have large sheets of material that you need to cut down to smaller pieces. For instance, if you need to cut a 4ft x 8ft sheet of plywood down into smaller parts of a cabinet.

You can also use a track saw to rip down large boards. For example, if you need to turn a 2x12 into a 2x6, you could use the track saw to rip the board in half lengthwise. Or position the track at an angle to cut off a corner, like for this kids bookshelf I made.

The track saw is also great for establishing a straight edge on an irregular board, such as rough lumber or live edge slabs. The flat back of these live edge floating shelves was created with a track saw.

In a small workshop, a track saw can replace the need for a larger table saw, or even replace the table saw altogether! You can find out more about the difference between a track saw vs table saw here. You don't need to account for infeed and outfeed space on either side of the saw, so you can work in a much smaller area.

How Do I Use a Track Saw?

Each track saw may operate in slightly different ways. Get to know your track saw before you operate the tool!

Here are several guidelines for using your track saw:

- Safety - Wear safety glasses and ear protection. Make sure you have enough space to make the cut and check that your material is stable.

- Set up your work area - I place a sheet of 2" thick rigid foam insulation on top of my workbench whenever I'm using the track saw. This protects the surface from getting cut up, and also supports the board and prevents it from pinching the blade. It's also stiff enough to use as a work surface across two sawhorses if I'm outside.

- Mark your cut line - Measure the desired width of the board, and mark your cut line on the board. Keep in mind that the rough side of the cut will be on top of the wood. To save time and increase the accuracy of repeat cuts, consider getting parallel guides for your track saw.

- Align the track - Mark your cut line on the board and place the track on the keep side of the line. The blade will cut away some of the material (called the kerf) and you'll make the board slightly too short if you cut from the wrong side!

- Check for square - If you're making a 90 degree cut, check that the track is square to your reference edge with a speed square. You can attach a track saw square to the guide rail to speed up this process and make your cuts faster!

- Set your blade depth - Set the plunge depth of the blade so it just clears the material. Some track saws have a button you can press to make a score cut. The score cut is a shallow first pass that breaks the wood fibers. The score cut can ensure you get the cleanest possible cut!

- Make your cut - Place the saw onto the track, making sure it's properly seated in the groove. Using a steady motion, bring the saw to full power and make the cut.

To learn more about how to use a track saw, check out the video below!

Frequently Asked Questions about Track Saws

Can I Use a Track Saw Without a Track?

Yes, you can use a track saw without a track. The saw will function the same as a circular saw when used this way.

The Festool track saw even has a separate depth setting for use without the track. It takes into account the height of the track and adjusts accordingly, so you don't accidentally cut through your workbench.

How Does a Track Saw Stay in Place?

Track saws stay in place through nonslip strips on the underside of the track. The sticky portion of the track saw does not leave a mark or a residue on your surface.

If you're worried about the track slipping, especially on slick surfaces like prefinished plywood or melamine, you can use special clamps to hold the track in place without interfering with the cut. These ones from Bessey slip into the groove in the underside of the track and clamp it down tight with a few quick squeezes.

Are Track Saws Safer than Table Saws?

Yes, track saws are safer than table saws. Though still dangerous, the blade is much less exposed in a track saw than it is in a table saw. You can see in this side view that the blade is completely encased inside the housing, until it's plunged down into the wood during the cut.

Many track saws also have some sort of anti-kickback technology. Older models of the Festool track saw have a riving knife behind the blade. The newer model has anti-kickback sensors that stop the blade instantly if the saw leaves the track unexpectedly.

What is a Circular Saw?

A circular saw can be used for all the same functions as a track saw, but doesn't necessarily do them quite as well.

If you're on a budget, you can turn your circular saw into a makeshift track saw with straight edge guide. You can make your own circular saw jig, or buy one instead.

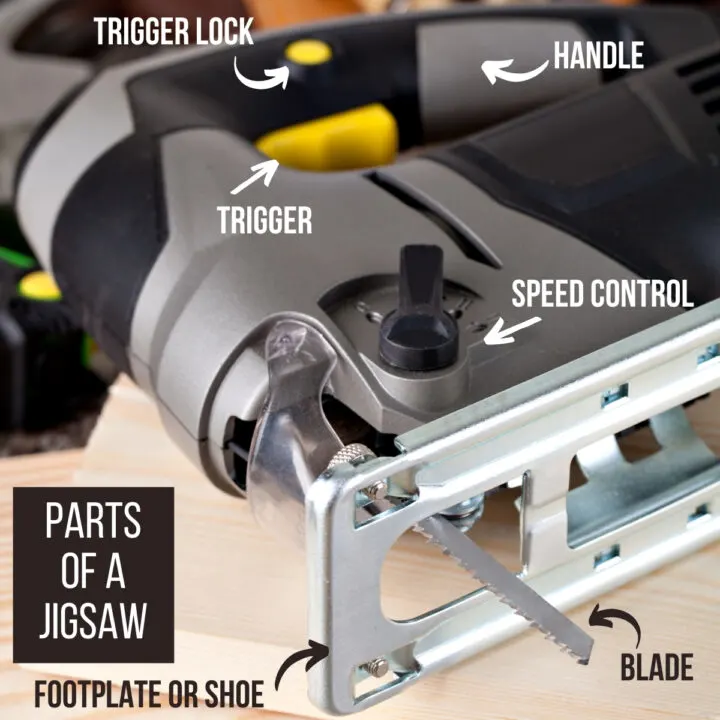

Here are several parts of the circular saw and how they differ from the track saw:

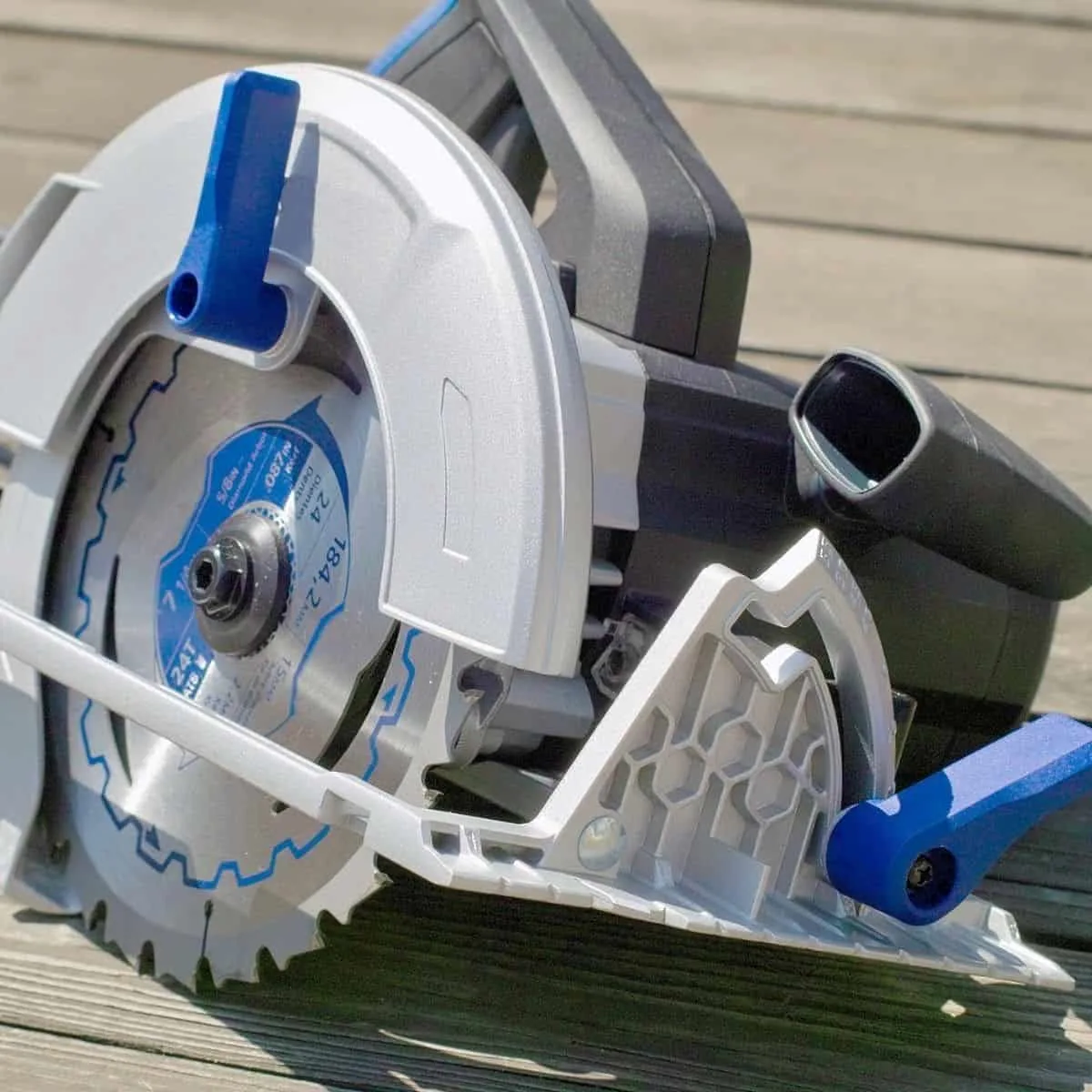

- Blade - A circular blade comes in many sizes and types, depending on what you plan to cut. It is always exposed in the front, unlike a track saw where the blade retracts inside.

- Deck - The deck or base plate of the circular saw will glide across the wood; the track saw glides across a track. You raise or lower the deck of the circular saw to alter the blade's depth, instead of adjusting the plunge depth of a track saw blade.

- Dust collection - Most circular saws don't have any! The blade throws all the sawdust back at you, creating a huge mess and a potential health hazard. Always wear a dust mask to prevent sawdust from getting into your lungs when cutting with a circular saw. This is the one I use!

When Should I Use a Circular Saw?

A circular saw works great for making long rip cuts, beveled cuts, plunge cuts, and cross-cuts. However, it's better suited for construction rather than building furniture.

The price for a good circular saw will be around $150. The track saw can cost $500 or more. A circular saw is a much more cost-effective tool, which is great for a beginning woodworker. If you don't need the ultra-precision of a track saw, then your money will probably be better spent on a quality circular saw.

However, a track saw can potentially replace a circular saw, a miter saw, and a table saw! If you're short on space, this is a great option. If you're curious, check out my article on the differences between a circular saw and a miter saw.

How Do I Use a Circular Saw?

Here are some guidelines to follow when operating your circular saws. Circular saws are dangerous tools if misused. Be sure to understand your saw and practice your cut before you begin.

- Safety - Remember safety goggles and ear protection. You'll also need a dust mask, especially if you're cutting indoors. Circular saws create a ton of sawdust!

- Plan your cut - Whether using a jig or not, be meticulous about planning your cut. Remember to measure and account for the thickness of the blade. The blade should cut on the waste side of the cut line.

- Choose the right blade and settings - Do you need a blade for rip cuts? Cross-cuts? You should match the type of blade to the type of cut you plan to make for the best results. Also, before the cut, set your blade depth so it just clears the thickness of the material.

- Secure your material - Nothing should be sliding around! Also consider where your material will go after you've made the cut. If your board is across two sawhorses and you cut down the middle, the two sides may pinch the blade and cause dangerous kickback. Support the board throughout the cut.

- Make your cut - Following the guide marks on the deck of your circular saw, start the saw to full power and begin your cut. Keep a firm grip and move at a steady pace - let the saw do the work!

To learn more about how to use a circular saw, check out the video below!

Frequently Asked Questions about Circular Saws

Here are some common questions about circular saws.

How Much do Circular Saws Cost?

Circular saws can cost anywhere from $60 on the low end to $300 for more powerful saws. I recommend you save up and get a quality circular saw! But if you're planning to buy an expensive circular saw, you might want to consider spending a little more to get a track saw instead.

Can You Use a Circular Saw without a Table?

Yes, you can use a circular saw without a table. However, the key is to make sure your project is properly secured. A large piece of thick foam insulation across two sawhorses works well, as it supports both sides of your project while allowing the blade to make a clean cut.

How Do You Store a Circular Saw?

You want to be careful not to bend the circular saw blade that protrudes from the bottom. Stress on the blade from leaving it sitting at an angle for long periods of time can cause it to shift out of alignment.

This DIY circular saw storage rack allows the saw to rest flat on the base plate with a slot for the blade. It's really easy to make with scrap wood, and would be a great first project with your new circular saw!

Overall, track saws are basically just high-precision circular saws. I'd recommend starting with a circular saw, then upgrading to a track saw if you're becoming frustrated with your results. I know plenty of woodworkers who create beautiful projects with just a circular saw, but I'm not one of them! 🙂 A track saw gives me the professional results I'm looking for, and is quicker, easier and safer to use.

Check out these other woodworking tutorials!